Molding, mold making, injection molding machine manufacture

Checking for PL (Parting Line) surface contact, checking for distortion of molds and molding machines

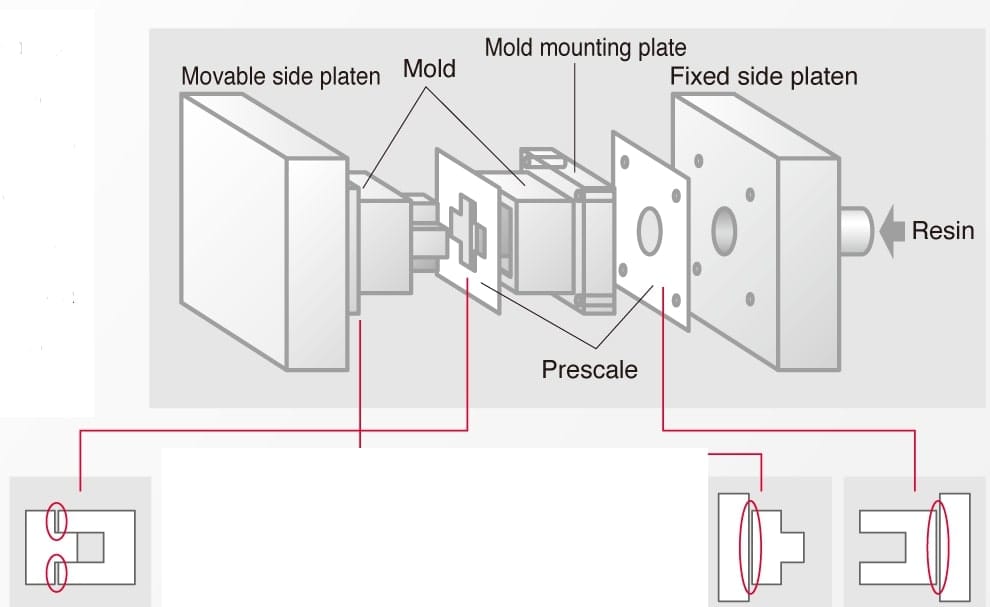

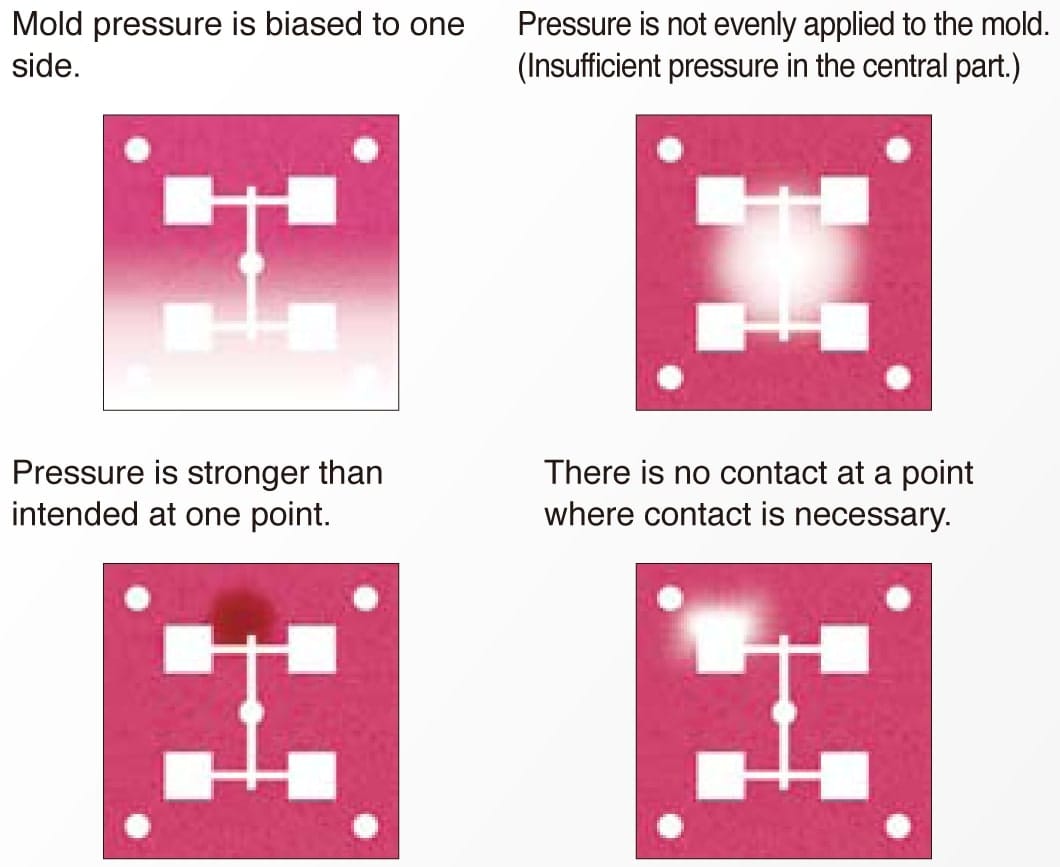

- Since molds are composed of multiple parts, dimensional errors of each part tend to accumulate in the thickness direction. This means that the precision of the height of each part of the PL surface can deviate significantly from its intended value, resulting in excessive contact pressure, the failure of parts to make necessary contact, or the generation of burrs.

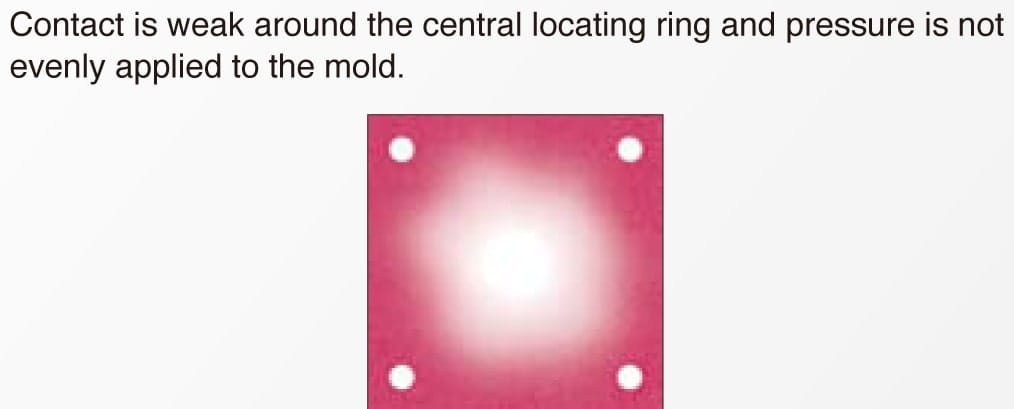

- When force is applied to clamp a mold, the platen tends to bend, which in turn causes the mold to bend. As a result, the thickness precision of the molded product deteriorates, leading to uneven wear and shortened mold life.

Product used: Prescale (LW, MS, HS)

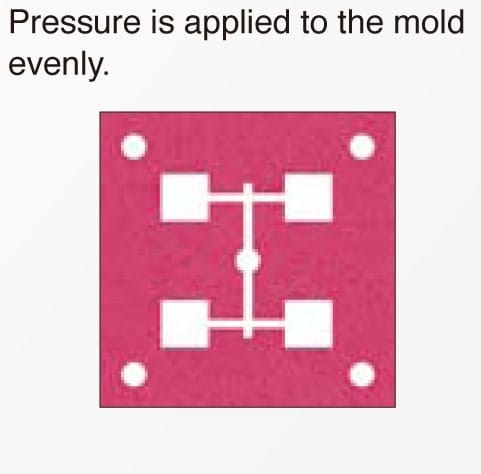

- When a new mold has been fabricated, or during production, insert the Prescale between the PL surfaces and measure the pressure distribution. (Application Example 1)

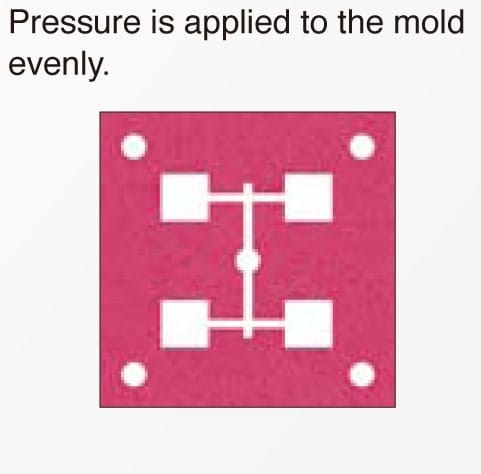

- To check the impact of platen bending, insert Prescale between the platen and the mold and measure the pressure distribution. (Application Example 2)

Application Example 1

Checking mold PL surface contact

[Not good]

[Good]

Application Example 2

Checking contact between mold and fixed side platen (movable side platen)

[Not good]

[Good]

1

When fabricating new molds, it is possible to produce ideal molds with even contact over PL surfaces.

2

Thickness precision and prevention of burring is improved, resulting in finished products of higher quality.

3

Effective mold life is lengthened.

4

The degree of platen bending and contact with mold can be easily checked.

Without using Prescale

Since PL surface contact cannot be checked or adjusted, burring of finished products occurs easily, and thickness precision is limited. In addition, mold life tends to be relatively short.

Using Prescale

The ability to check contact using Prescale and thereby adjust PL surfaces makes it possible to determine the causes of defects in finished products, thereby improving plant utilization and to increase mold life. Prescale also makes it easy to check the degree of platen bending and contact with the mold.