Feel the Pressure

A Force Sensing Resistor is an electronic device whose resistance changes when a force or pressure is applied to it. Generally, force sensing resistors are constructed from two film layers that are assembled together. A resistive material is coated on one film layer, and an electronic circuit is coated on the second film layer. These two layers are joined with a bonding agent.

The circuit resistance is quite high in the absence of pressure. However, the resistance drops when pressure is applied to the sensor. This drop is caused by the resistive material being pressed together and against the circuit. The resistance drop is proportional to the amount of pressure being applied.

Figures 1 through 3 show various force sensing resistors that have been manufactured by Sensor Products, Inc. The output of the sensors is collected and interpreted by Tactilus®, Windows®-based software. This system includes signal-conditioning electronics, and it can collect data as rapidly as 1,000 readings per second.

| Fig 1: Force Sensing Resistor Used for Bolt Tension Evaluation | Fig 2: Tactilus® Sensing Element Used in Pressure Sensing Mats. | Fig 3: User-constructed Array of Four Force Sensing Resistors. |

There is a complete software library that provides:

- 2D, 3D, and 360 degree image rendering with extensive user control,

- Force integration and average pressure,

- Highly programmable report generator,

- Local point and region-of-interest (ROI) analysis,

- Max, minimum and average values,

- Pressure vs. time graph and pressure histogram,

- Sophisticated calibration control,

- Easily exportable data to Excel, ASCII, or Access formats

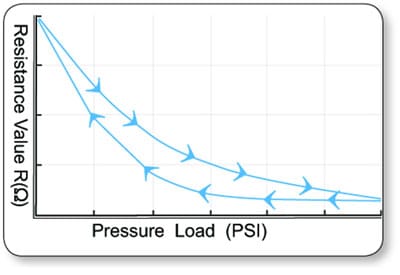

Switching is another application for force sensing resistors. The Tactilus® solid state sensor/switch allows the user to control any device, equipment or peripheral that allows for operation in variable states. Any application where a user would benefit from going beyond a simple on/off control is a viable candidate for these ultra flat switches. Tactilus® switches are low profile (paper thin), customizable to accommodate limited real estate, economical, draw minimal current, and last for thousands of uses. As the user lightly depresses the switch with their finger, the resistance value drops, allowing current to flow (see Figure 4).

Fig 4: Graph of Resistance versus Pressure

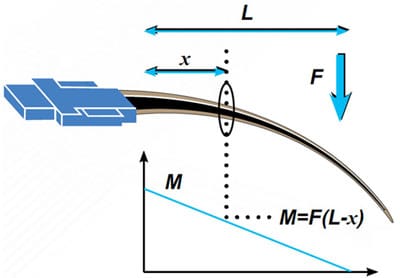

Tactilus® Flex is ideal for any application that requires the measurement of a bending, deflection, or acceleration. This force sensing resistor captures a bending moment and produces a signal proportional to that bend as shown in Figure 5. This sensor uses a patented, fretting process to repeatedly indicate the degree of a bending moment. Other sensors are sometimes capable of indicating when they are bent, but none of them are specifically designed for this purpose, and they fail to be repeatable or accurate. Common applications include biomechanics, ergonomic research, air or fluid flow, and industrial controls.

Fig 5: Output Based on the Amount of Bend