Manufacture of mobile phones, smart phones, and tablet computers

Checking uniformity of assembly jig pressure

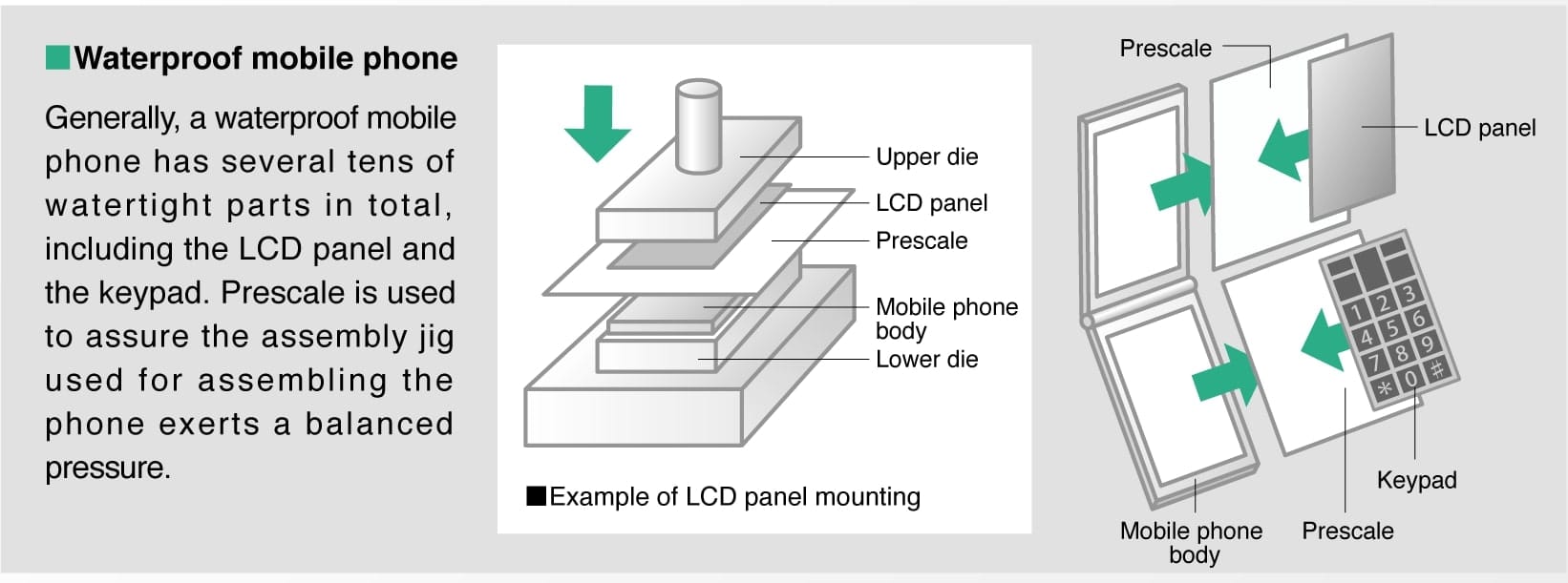

As mobile phones become compact and thin, the demand for waterproof phones is growing. However, the assembly of waterproof mobile phones requires stricter tolerances then those of non-waterproof devices. Also, waterproof construction requires additional parts, so the assembly of waterproof devices involves more process, which increases the probability of waterproofing malfunction due to assembly defects. Therefore, ensuring that uniform pressure is applied by the assembly jigs during the assembly of waterproof devices is an important issue.

Product used: Prescale (Ultra super low pressure LLLW, Super low pressure LLW, Low pressure LW)

- The parts of the mobile phone is to be assembled are loaded onto the assembly jig.

- A sheet of Prescale, cut to the appropriate size, is inserted.

- Pressure is applied by the assembly jig.

- The Prescale is removed, and the color density indicates the evenness of the mounting position and the overall pressure balance.

- If the pressure balance is poor, the jig pressure balance is adjusted, and another check is performed using Prescale

- When the density of the developed color is even, full-scale production can begin.

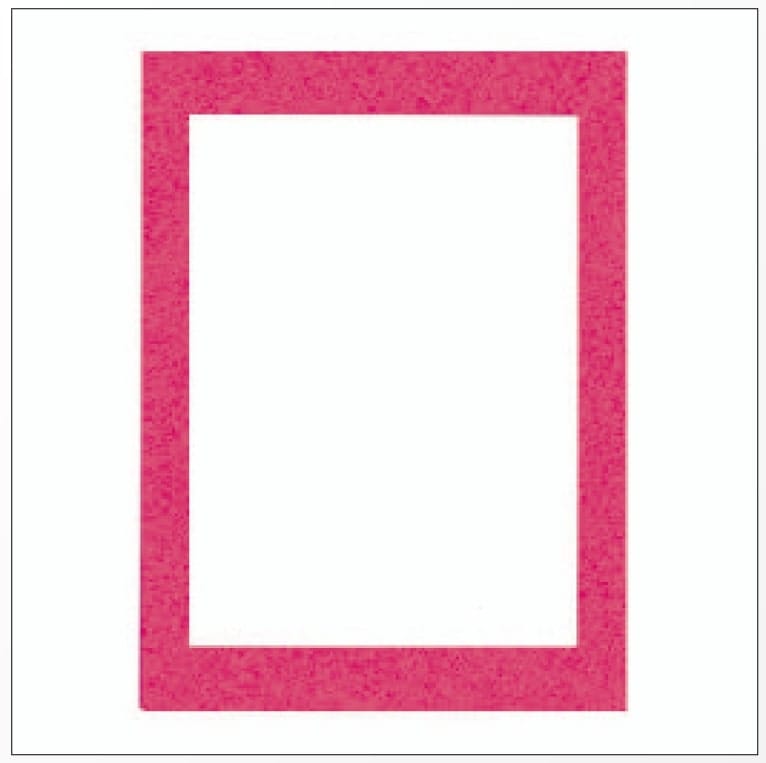

[Good]

Pressure is evenly applied

[Not good]

Pressure is unevenly applied

Higher yield, higher product quality, and higher precision

Lower variance between individual products

Less time needed to analyze defects

Without using Prescale

Since the evenness of the mounting position and the pressure balance of the jig are not checked before commencing assembly, the finished product after assembly may not be sufficiently watertight.

Using Prescale

Since the evenness of the mounting position and the pressure balance of the jig are checked before commencing assembly, the finished product after assembly will definitely be watertight.