Semiconductor manufacturing (die bonding)

Adjustment of chip suction jig (die collet) for use in die bonding

When semiconductor chips are bonded to a lead frame (LF) or substrate, the chips are removed from a wafer after dicing by use of a suction jig, known as a “die

collet” and then transported. If the suction nozzle is not applied evenly to the semiconductor chips, problems may occur when the chips are removed, or the chips

may become flawed. As wafers become thinner and more easily breakable, greater care is required.

collet” and then transported. If the suction nozzle is not applied evenly to the semiconductor chips, problems may occur when the chips are removed, or the chips

may become flawed. As wafers become thinner and more easily breakable, greater care is required.

Product used: Prescale (Ultra Super Low Pressure LLLW, Super Low Pressure LLW)

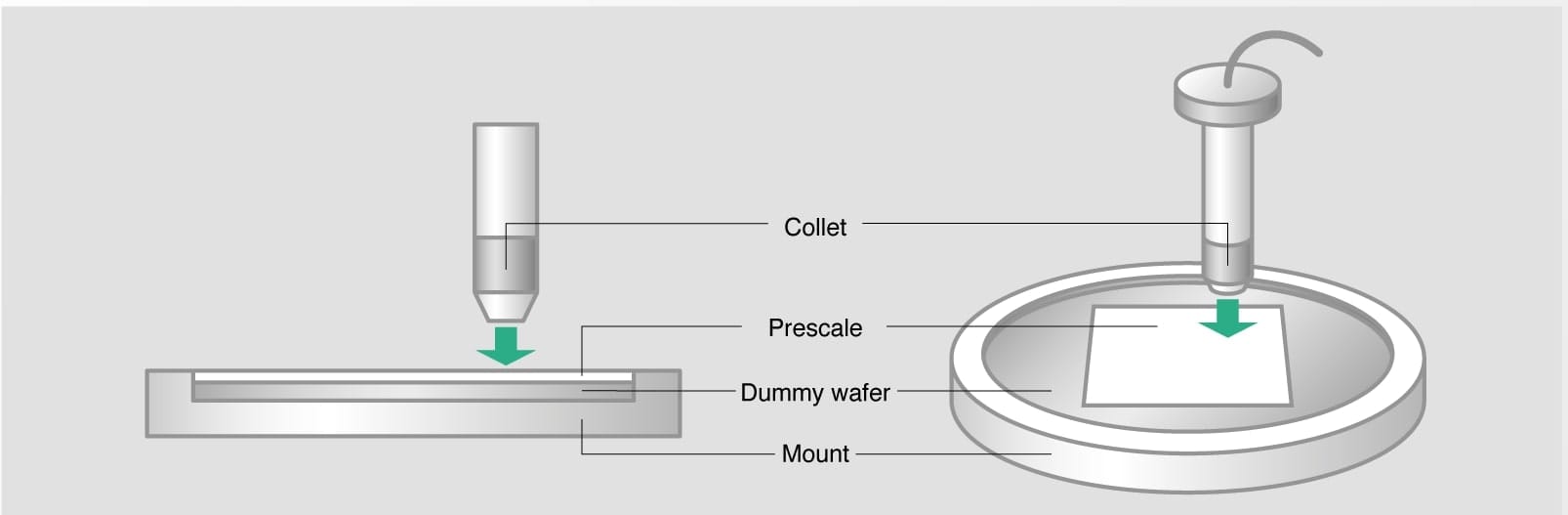

Create a plate-shaped dummy wafer that will have a height (thickness) equal to the production wafer after adding 200-μm-thick layer of Prescale film.

When a suction nozzle needs to be changed, place the dummy wafer on the bonding device, insert Prescale (LLW. LLLW), and then perform the suction operation.

Check the evenness of the film coloring after suction application and confirm whether the suction nozzle was applied evenly to the wafer.

It is possible to determine whether the suction nozzle will be applied evenly to the wafer (semiconductor chip) before starting production. This means that

transport problems and chip damage can be actively prevented.

transport problems and chip damage can be actively prevented.

[Not good]

Suction nozzle is applied unevenly

[Good]

Suction nozzle is appled evenly

When the suction nozzle is changed, transport or quality problems may occur due to the uneven application of the suction nozzle to semiconductor chips. This leads to

the following:

the following:

Loss of quality

If defects are missed at inspections, defective products may be shipped

Loss of materials

If defects are found at inspections, materials used in defective production and line changing will be lost.

Loss of time

Taking corrective action by trail and error can take up to a day

Without using Prescale

Die bonding is started immediately after the suction nozzle is changed. Since the evenness of nozzle application cannot be checked, problems may not be discovered until a process stoppage occurs (due to a transport issue), or until defects are found in the final inspection, In addition to the occurrence of defects, time is lost when adjusting equipment.

Using Prescale

When a suction nozzle is changed, Prescale is used to verify nozzle fitment. Die bonding is only started after making adjustments. Thus, process/quality abnormalities due to suction-related transport can be prevented