Pressurex® sensor film needed to measure contact pressure variations across flip chip dies and bonding tools.

Undetected bonding pressure variations can result in poor or open flip chip connections, reducing yield and long-term reliability while raising costs. Maintaining a uniform distribution of bonding pressure across a flip chip die assures chip to substrate coplanarity, optimal bump compression, and a controlled, reproducible die to substrate gap. Pressurex® pressure indicating sensor film is a valuable assist to today’s flip chip bonders which lack the capability to measure pressure variations across the bonding tool but instead rely on average pressure with the assumption that it is uniformly distributed. Now a proven control measure in wafer-to-wafer bonding, Pressurex® could extend similar low-cost coplanarity and uniformity control to flip chip bonding.

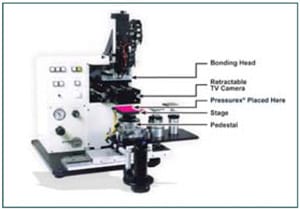

Pressurex® Reveals a Pressure Profile Across the Surface of a Flip Chip Bonder

Pressurex® pressure-indicating sensor film provides a convenient, accurate, repeatable, and low cost control for both bonding and coplanarity. The thin flexible sensor film reveals pressures from 2 – 43,200 PSI (0.14 – 3,000 kg/cm²). When placed between the contacting surfaces of a flip chip bonder, it instantaneously and permanently changes color directly proportional to the amount of pressure applied. The precise pressure magnitude and distribution is then easily determined by comparing color variation results to a color correlation chart (conceptually similar to interpreting Litmus paper).