Article: U.S. Tech

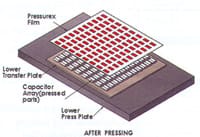

Capacitors after being pressed

Pressurex® film revealed the uneven distribution of pressure across the press plates.

As an innovator of capacitor technology, SB Electronics designs and manufactures products that are on the cutting edge of today’s demanding electronics applications. To maintain continuous improvement of its manufacturing processes, David Bryan, Manufacturing Engineering Manager for SB Electronics, recently specified Pressurex®, a tactile surface pressure indicating sensor film from Sensor Products Inc.

Many of SB Electronics’ radial lead products are designed to take up the minimum amount of space on printed circuit boards. This is often done by flattening the round capacitors’ profile by pressing them between aluminum plates. A higher than expected reject rate led the quality department to contact engineering to troubleshoot and improve the process.

Out of Spec

"After histograms indicated that some of our tighter tolerance parts (±1 percent capacitance) were going out of spec during our pressing operation, and making some initial dimensional measurements using conventional measuring equipment (calipers and micrometers), I wanted a better way to determine exactly what was happening with the surface pressure during this process," says Bryan.

Bryan ordered Pressurex®, a thin flexible sensor film that instantly captures and permanently records pressure distribution and magnitude between contacting or mating surfaces. The film measures pressure from 2 to 43,000 PSI (0.14 to 3,000 kg/cm²). For his test, Bryan specified "Super Low," which measures pressure from 70 to 350 PSI (5 to 25kg/cm².

Bryan inserted a sheet of Pressurex®, which is similar in thickness to paper, on top of the capacitors and between the press plates during a product run.

After the pressing operation, when Bryan examined the film, it had changed, showing different intensities of color, with the color change directly proportional to the actual pressure applied. Bryan was able to determine the precise pressure magnitude by comparing the color intensity to a color correlation chart (conceptually similar to interpreting Litmus paper). "I could visually inspect Pressurex® and prove the press plates weren’t flat and were causing uneven pressure distribution," said Bryan.

Stimulated by this discovery, Bryan wanted to statistically analyze the surface pressure further. He asked Sensor Products to use their Topaq® Image Analysis System, which consists of a Windows-based software and scanner, specifically calibrated to read and further interpret the film. Interpreted images are accompanied by a wealth of graphical and statistical data that are extremely valuable for contact pressure tests. With Topaq®, small and problematic areas can be carefully scrutinized, as well as the entire interfacial surface.

Pressure Not Uniform

Through Topaq®, histograms further revealed the pressure was not uniform across the plates.

Bryan continues to use standard tools such as micrometers and calipers, but is now asking that Pressurex® be included as an ongoing ISO quality control protocol. In the past, he had used the film to evaluate bolted flange designs for custom fittings in vacuum systems.

Pressurex® allows for rapid and easy determination of compression magnitude and distribution. The film has many uses in multi-layer printed circuit board assembly, including analyzing contact uniformity in the design and production of printed circuit board assemblies. In wafer fabrication, Pressurex® is often used to verify flatness, revealing lamination press problems caused by inconsistent bonding pressures. It can successfully predict and evaluate load distribution, revealing problems such as the overloading of connector contacts, standoffs, and component solder joints. The sensor film is used in many electronic and industrial applications, such as assessing contact inconsistencies in heat sinks, gaskets, clamps, bolted joints, heat sealing elements, nip rolls and welding heads. New uses for Pressurex® are discovered daily. The use of Pressurex® can significantly improve quality and reliability levels during prototyping, development and production processes, while at the same time, helping to reduce production costs and budget over-runs. This will contribute to leaner, simpler, and more accurate manufacturing and testing methods.

Headquartered in New Jersey and established in 1990, Sensor Products Inc. manufactures and distributes tactile pressure sensing solutions. The company’s customized and off-the-shelf products are installed within all of the Fortune 500 industrial companies as well as thousands of smaller manufacturing firms. The sensors are used in applications as diverse as tire testing and semiconductor manufacturing and from R&D labs to space missions. In addition, the company provides in-house and on-site stress and pressure mapping analysis, as well as a variety of technical seminars.

SEE Inc., dba SB Electronics, designs and manufactures Film Capacitor Products. The company has developed unique technology (patent pending) in pulse power design and continues to introduce new technologies to support the Homeland Security, Electric Utility, Energy Efficient Lighting, Medical and Automotive/e-drive markets.