Articles: UK Intpress (UK)

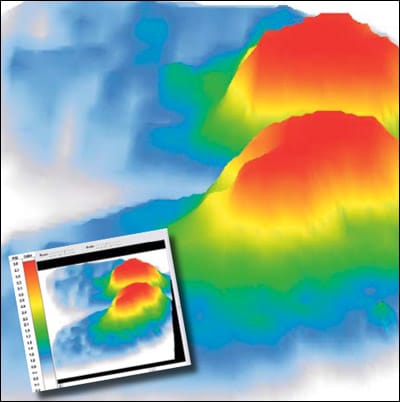

The image vividly shows the surface distribution and magnitude pressure of the buttocks, thighs and legs of a person seated. Jason Blume, Electronic Systems Program Manager, says, “The even distribution of pressure is very evident and supportive of comfort.”

Measuring seat comfort used to be an exclusively subjective experience. However, recent advances involving tactile surface pressure measurement now make it possible to scientifically measure comfort with a high degree of accuracy.

Railway design engineers and manufacturers can test the design and materials for a seat and maximise ergonomic comfort by using electronic surface pressure sensor systems. Edward (‘Ted’) Claghorn, market development manager of MTI Specialty Silicones, recently chose the Tactilus® Bodyfitter surface pressure mapping system from Sensor Products Inc to test his silicone seat cushions for the Victoria Line of the London Underground.

Claghorn had previously used other tactile pressure sensors and chose Tactilus® because it was able to show with greater precision and in a variety of colourful visual formats the actual magnitude and distribution of pressure over the entire body surface that came into contact with the cushion.

Vadim Shaylt of Sensor Products Inc sits on the Blue Tactilus® Pad connected to a hub, which wirelessly transmits the surface pressure data to the laptop

“Numbers tend to blend together, and average minimum and maximum pressure readings don’t tell the whole story,” says Claghorn. “you look at three-dimensional surface pressure distribution maps, there is a huge difference. don’t have to spend hours analysing data. the visuals provide a compelling argument against the comfort of your product.”

which is essentially an ‘electronic skin’ with more than 1,000 sensing points, was placed on top of the different foams that had been inserted into the cushions. Upon activation, the sensors immediately recorded and transmitted the data to the system’s powerful Windows-based software which is essentially an ‘electronic skin’ with more than 1,000 sensing points, was placed on top of the different foams that had been inserted into the cushions. Upon activation, the sensors immediately recorded and transmitted the data to the system’s powerful Windows-based software.

“The pressure mapping showed us how evenly the pressure is distributed throughout the buttocks and thighs,” says Claghorn. “The report stimulated our thinking about ergonomic design. Since this pressure mapping can be done on any kind of material, the steel pan the cushion rests on could also be subject to design modification and testing with Tactilus® in the future.”

While Tactilus® has many different applications for measuring pressure between any two contacting or mating surfaces, Bodyfitter is especially suited for seating analysis, measuring pressures from 0-4 PSI (0.28 kg/cm2). The seat surface backrest and headrest can all be measured simultaneously.

Tactilus® is a matrix-based tactile surface sensor that works by the principle of piezoresistance. It employs sophisticated mathematical algorithms that intelligently separate the signal from noise, and advanced electronic shielding techniques to maximise environmental immunity to temperature and humidity.