Ph.D. student eng. – TRANSILVANIA University in Brasov – Faculty of Wood Engineering

Address: B-dul Eroilor nr. 29, 50036 Brasov, Romania

E-mail: [email protected]

Prof.dr.eng. – TRANSILVANIA University in Brasov – Faculty of Wood Engineering

Address: B-dul Eroilor nr. 29, 50036 Brasov, Romania

E-mail: [email protected]

Abstract:

Chairs made of solid wood belong to a category which requires special attention due to its frequent structural stressing. This study proposes the identification through load simulation of those structural elements, which can potentially become vulnerable. In this way measures can be taken during the design process to avoid eventual drawbacks and appropriate solutions can be found.

The chair types that were the subject of this analysis have a simple construction, being commonly used in various human activities, but also the sitting ergonomics were kept in mind. When determining their dimensions, standards, studies and existing research were followed. The chair types were chosen as follows: a chair without stretchers, one with lateral stretchers and a lounge chair.

The wood species for which the study was made is Fraxinus excelsior – ash wood, which shows average mechanical performance when compared to other hardwoods preferred by chair manufacturers. Its properties were used for a further analysis.

Identifying the areas of the chair structure which are stressed by the human body was necessary in order to simulate real-life conditions. The finite element method was used, with a dedicated software. The interpretation of results is able to prove the quality of the design process.

The proposed methodology may be applicable also for more complex chair structures.

Key words: chair; wood; structure; analysis; stress; Finite Element Method.

INTRODUCTION. CONSIDERATIONS REGARDING THE MAIN PHYSICAL PROPERTIES OF WOOD; CHOICE OF WOOD SPECIES FOR CHAIRS

The historical evolution of chairs as well as the intervention of modern designers has generated an impressive variety of models, and implicitly of structures, forms and sizes. The chair design process is a complex one, mostly based on details concerning ergonomics, design, wood properties, structure.

This study aims at answering for a good behaviour of the seating furniture, from the perspective of load resistance, when it is used in human activities and to become a starting point in exploiting the performances also of other structures. Unlike other furniture pieces, chair structures are much more exposed to dynamic external forces.

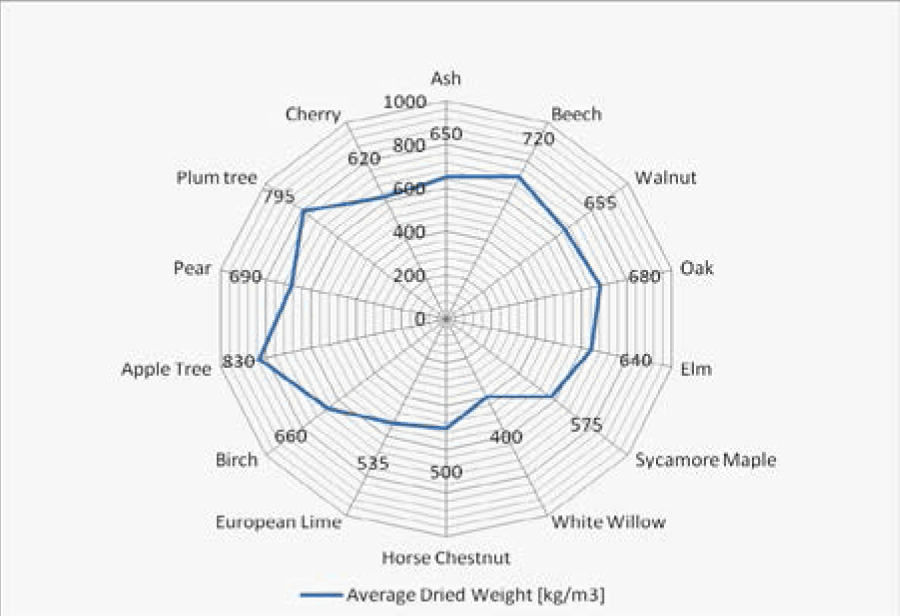

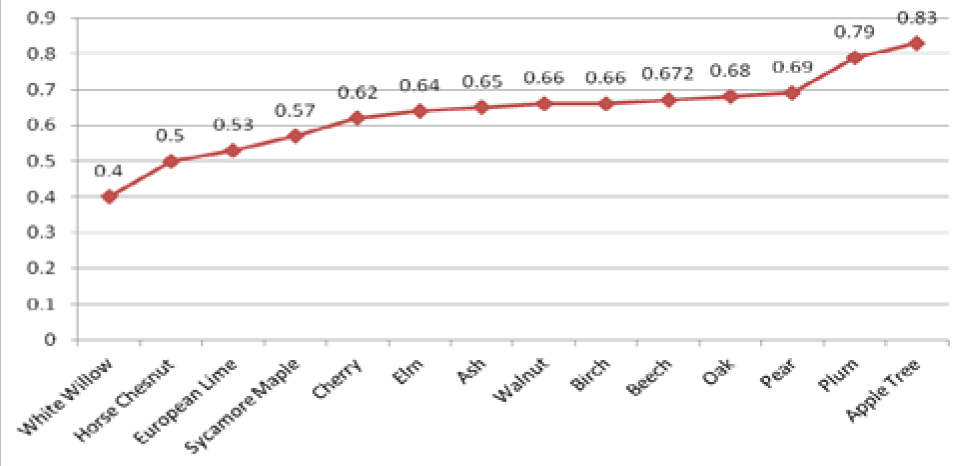

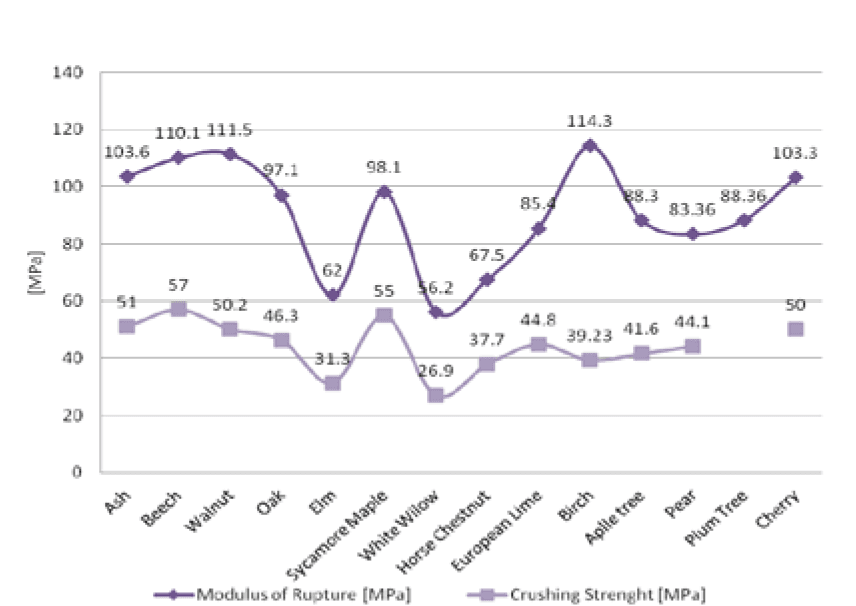

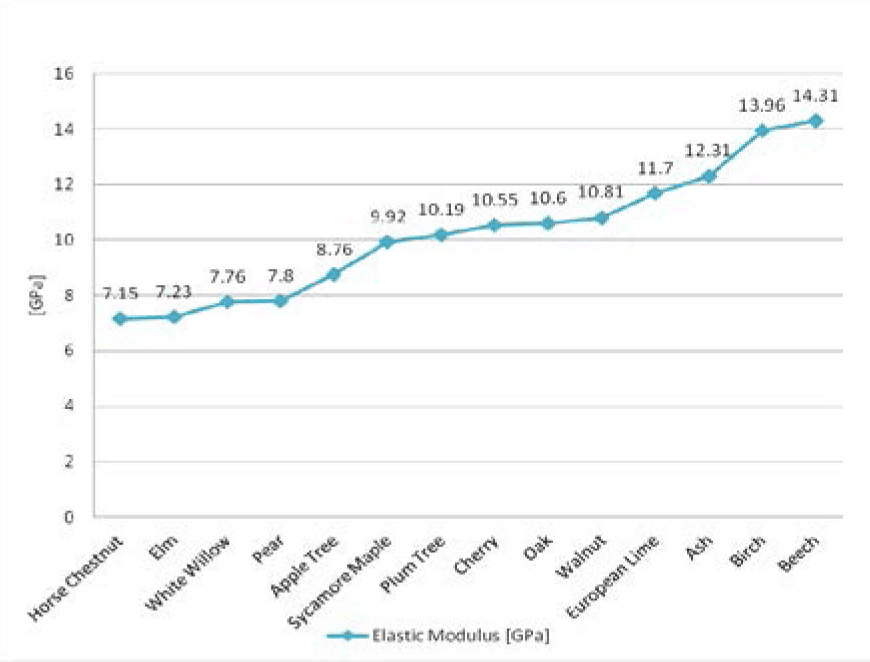

The main physical and mechanical characteristics of the hardwood to be chosen for wood chairs were taken into consideration. The most important wood species used for chair design are ash (Fraxinus Excelsior), beech (Fagus sylvatica), walnut (Juglans regia), oak (Quercus robur), elm (Ulmus procera), sycamore maple (Acer pseudoplatanus), white willow (Salix alba), horse chestnut (Aesculus hippocastanum), European lime (Tilia x europaea), birch (Betula pendula), also apple (Malus spp.), pear (Pyrus communis), plum (Prunus domestica) and cherry trees (Prunus avium). The mechanical properties and stress-resistance features can be compared with the help of the following diagrams.

Graphic summary of the average dried weight.

Graphic summary of the specific gravity.

The diagram of Modulus of Rupture and Crushing Strength.

The diagram of Elastic Modulus.

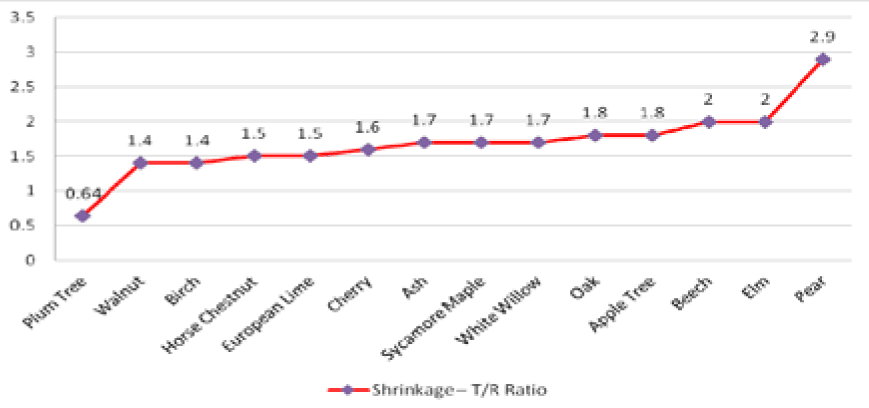

The Shrinkage – T/R Ratio different.

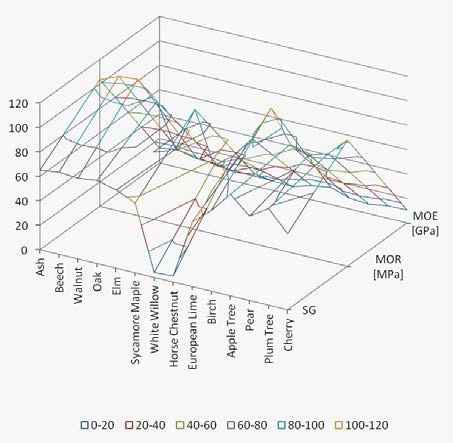

A spatial correlation between the specific gravity, modulus of rupture and elastic modulus of the various species can be made (Fig. 6).

The report of the species specific gravity, Modulus of Rupture and Elastic Modulus.

DEFINING THE GEOMETRY OF THE MODEL

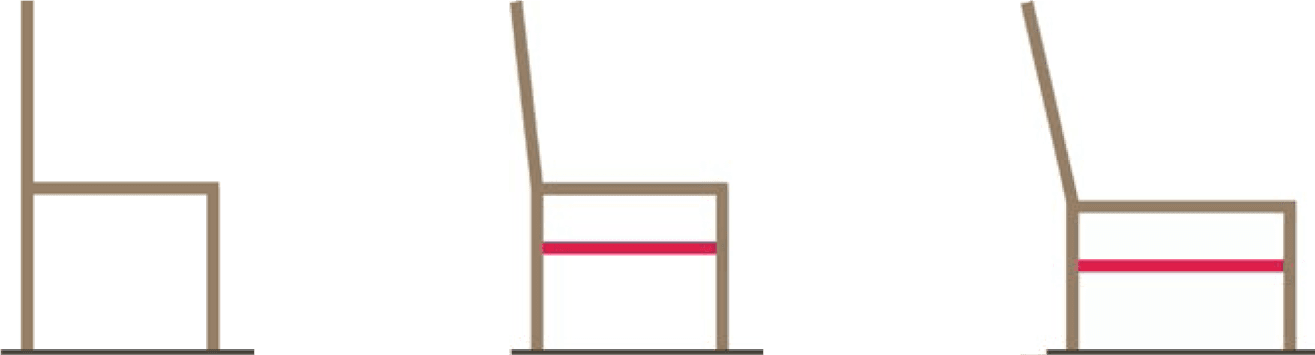

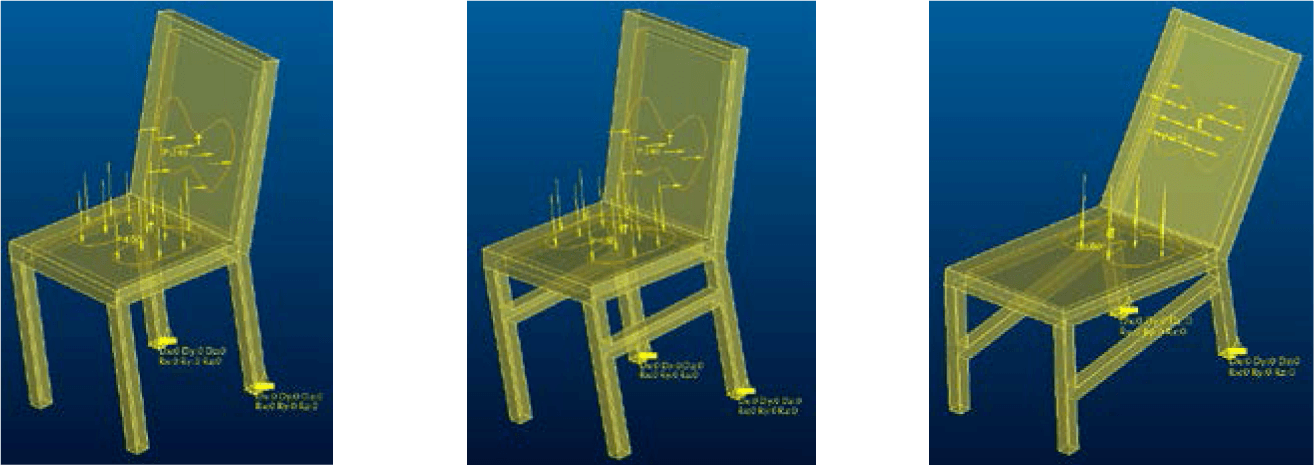

Fig. 7 shows two chairs (Fig. 7.a, without stretchers and Fig. 7.b with stretchers) and one lounge chair (Fig. 7.c), with a simple structure.

Usual types of chairs: a – Chair without stretchers; b – Chair with lateral stretchers; c – Lounge chair, with stretchers.

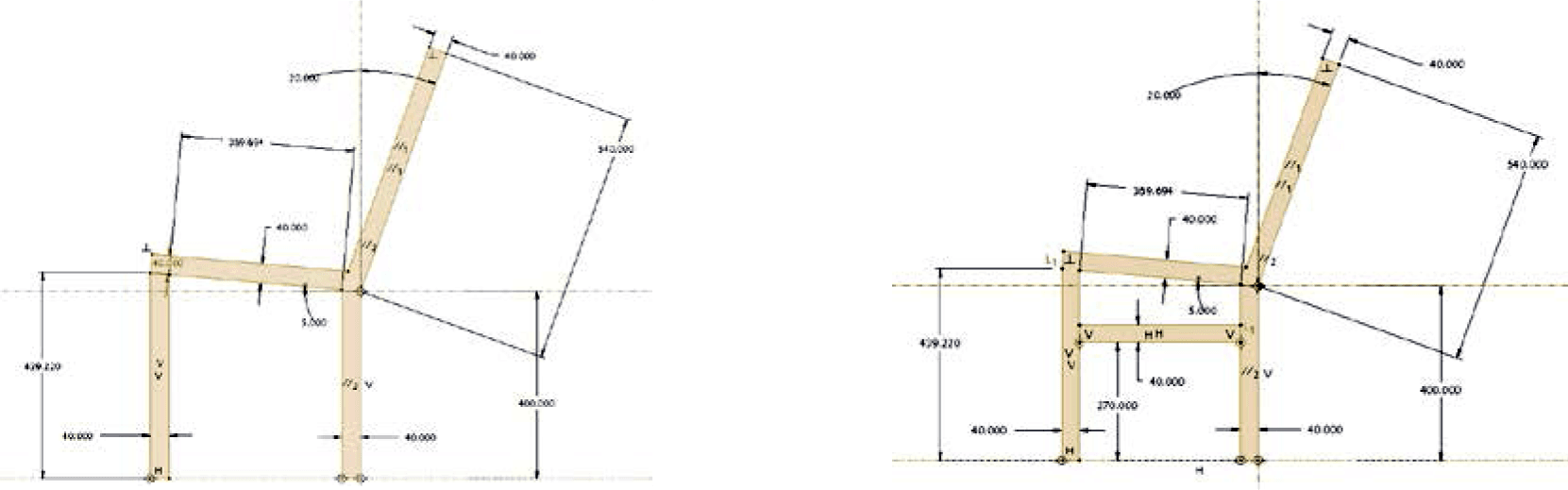

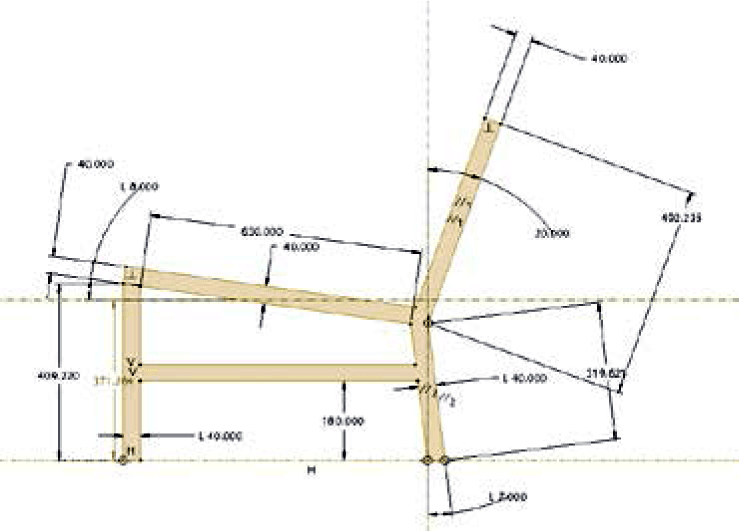

For generating the sizes, recommendations and dimensional studies concerning sitting ergonomics were kept in mind. (Fig. 8.a,b,c).

Dimensions recommended for chairs: a – Chair without stretchers; b – Chair with lateral stretchers; c – Lounge chair, with stretchers

The value of 40mm has been associated to the width of all elements.

BUILDING THE FINITE ELEMENT MODEL

The current research concerning details of the contact zones between the human body and the chairs indicates precisely the contact areas and distribution of forces. The results offered by these methods and software are useful in the process of analysis, because simulations can be made for various body weights and constitutions.

The Tactilus® Bodyfitter® offers a solution for finding the pressure forces in real-time and it’s capable of characterizing the pressure magnitude of the seat surface, back and rest simultaneously (Sensoprod 2014). The method uses pieso-resistive sensors which transmit the measured data to a computer, the visualization being made with a dedicated software (Fig. 9.a)..

The studies of ergonomics made for the Herman Miller company, producer of lounge chairs, demonstrate that a comfortable chair will produce pressure distributions for a wide range of users that show peaks in the area of the ischial tuberosities when the sitter is in an upright posture and areas of the back away from the spine when the sitter is in a reclining posture (Herman 2013) (Fig. 9.b).

The interaction of the human body with chair surfaces:a – Tactilus Bodyfitter, Screenshot of pressure distribution across a seat pad width (Sensoprod 2014); b – Herman Miller, Good pressure distribution in a chair (Herman 2013).

Identifying the zones where the pressure from the human body is high constitutes the necessary support for load simulation.

The imprints that concentrate the highest tensions for the seat and back can be loaded for compensation with static forces substantially higher than with dynamic ones. The choice of forces is that which is related to an 80kg human body, so for the seat these can be 6 times higher, measuring 480N, and 3 times higher for the back, measuring 240N.

A software that is able to generate a complex analysis is ProEngineer with the Pro Wild fire 2.0 module. The three types of chairs were modeled and loaded, the chairs having their rear legs fixed to the floor (Fig. 10).

Loading of the high-pressure areas

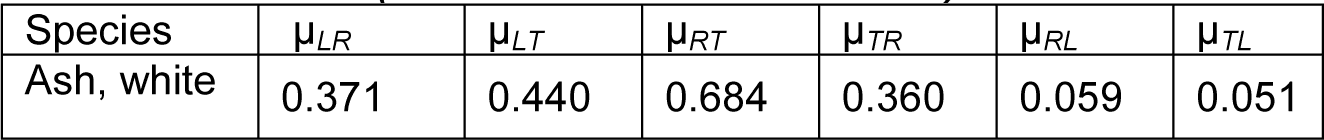

During the calculus a particular aspect became significant, namely the recommendation from the software’s documentation to use Poisson’s ratios. This approximation is necessary because the wood is an anisotropic material.

The ratio of the transverse to axial strain is called Poisson’s ratio. The Poisson’s ratios are denoted by µLR, µLT, µRT, µTR, µTR, µRL, µTL. The first letter of the subscript refers to direction of applied stress and the second letter to direction of lateral deformation (Table 1) (Conrad Forest Product 2014).

The average value taken in consideration for the Poisson’s ratios was 0.3275.

The other mechanical properties necessary for the analysis have the following maximum values: Yield Strength: 112 [MPa]; 112000 [mm kg/sec2^2/mm^2], Young’s Module: 18100 [MPa], Density: 650 [kg/m3] and the Thermal Expansion: 45E^-6/K.

RESULTS

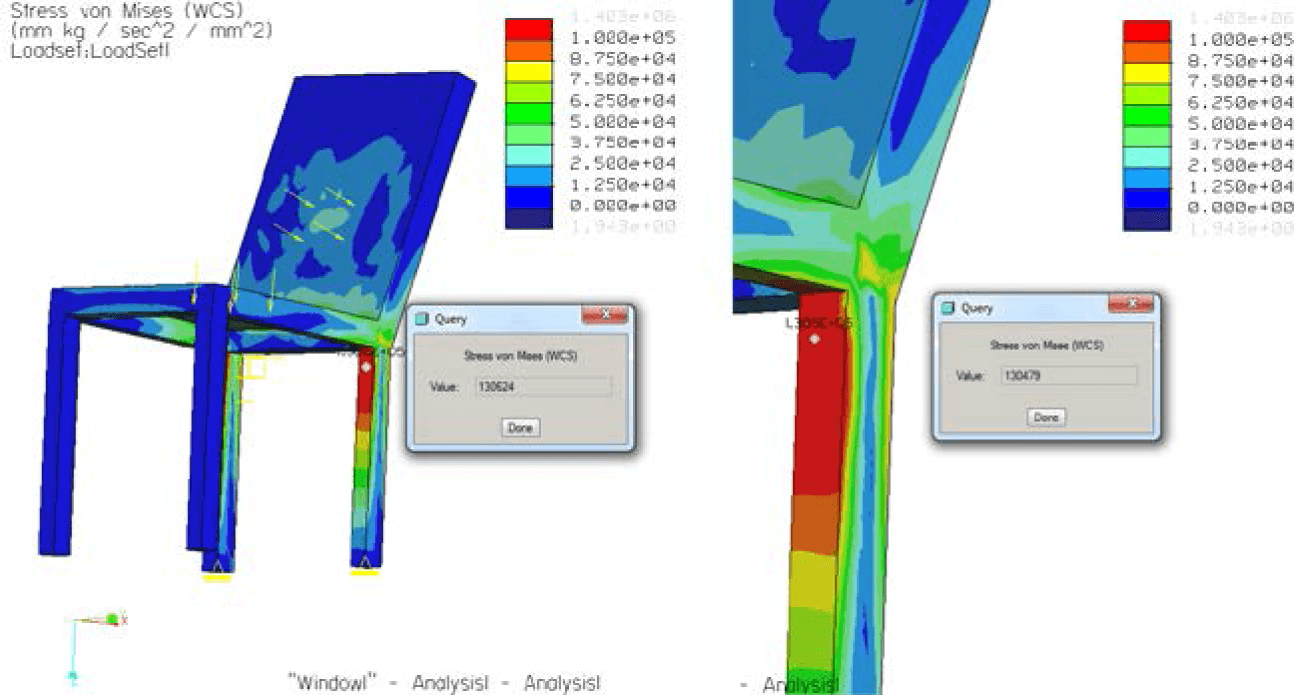

The results are interpreted as equivalent resistance (von Mises stress), representing N/mm2. It is a good indicator that assures a good behaviour of the loaded model if the maximum values are not reached.

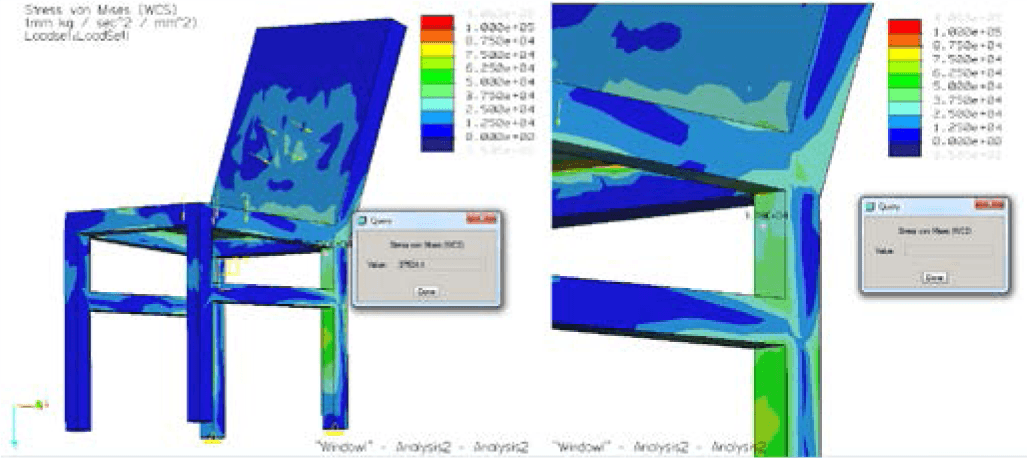

For the chair type without stretchers the critical point appears in the upper part of the leg, but doesn’t reach the maximum allowed value (Fig. 11).

Critical tensions for a chair without stretchers.

The chair having lateral stretchers behaves very well under load, reaching medium values (Fig. 12). Only a small area shows tensions, at the middle, by the joint between the seat and the back, but they are not critical.

Critical tensions for a chair with lateral stretchers.

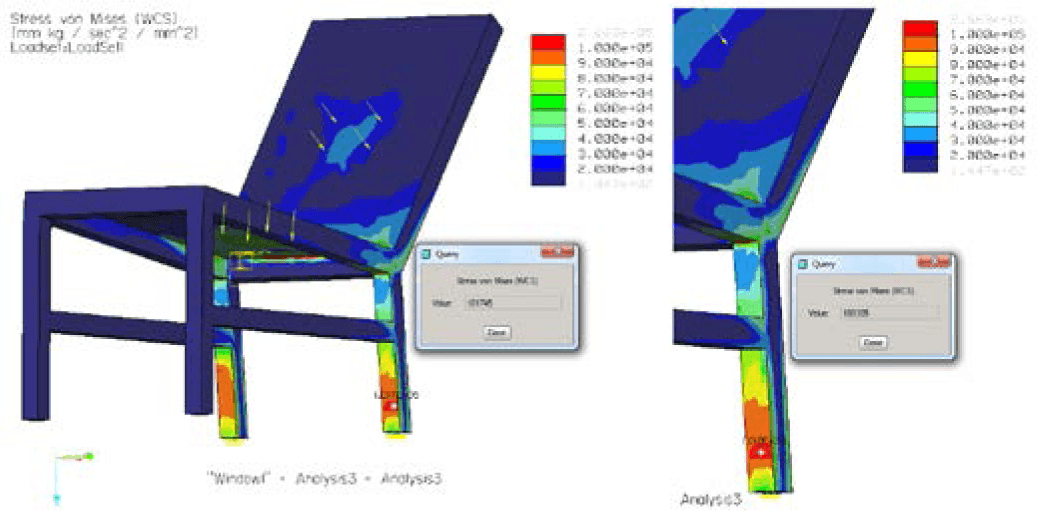

When loading the lounge chair we notice higher tensions in the lower part of the legs, but without reaching critical values (Fig. 13). Also at the joint between the back and the seat we see higher values but again they don’t reach the maximum.

Critical tensions for lounge chairs.

The presence of a lateral stretcher takes over the dangerous tensions from the rear leg, which leads to a more uniform distribution of stress in the upper and middle zones. Also the tensions inside the seat are below average.

It can be noticed the fact that due to the negligible tensions in the front legs the presence of a frontal stretcher is not needed for either of the models. The backrest is only stressed in the contact zone, having low values.

CONCLUSIONS

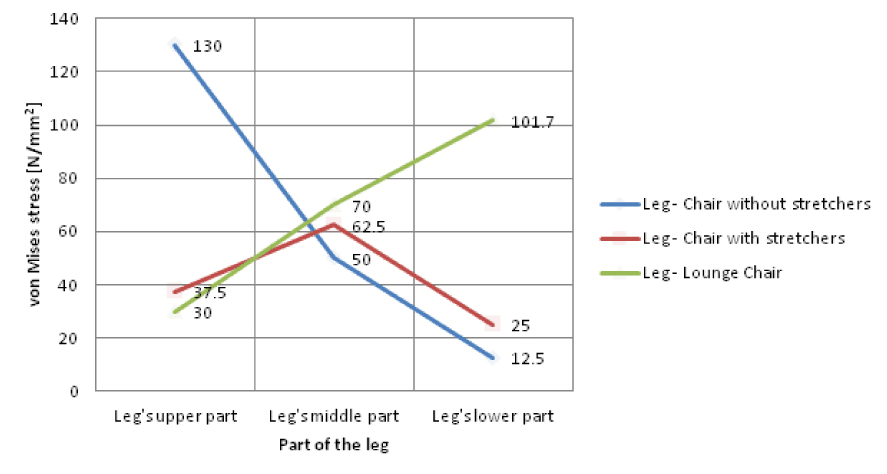

The highest tensions can be found in the rear legs. Along the height of the leg three parts can be diffrentiated which present risc zones. It can be observed that for chairs without strechers the upper part is closer to critical values and for lounge chairs the lower part presents average risc. The chair with strecher has the best behaviour, with average values. (Fig. 14).

Comparative analysis of tension variations in the rear leg for seating furniture models.

It is recommended to find solutions for these small drawbacks during the design process.

For safety reasons some constructive measures are recommended, or strengthening the joints between legs and rails, for example with corner brackets.

As a preventive measure when zones with hightened risc exist, the cross-section can be raised. The zones where the tensions are not high can be considered as having supradimensioned elements, so the cros-sections can be made smaller. These measures bring a change in the from and a new design can be pursued. The analysed wood species has been chosen as having average physical properties, respectively ash (Fraxinus Excelsior). Using species with better properties can lower the critical stress forces.

The Finite Element Analysis method has provided a good evaluation in the design phase, the values of the tensions being satisfying for all considered models.

REFERENCES

https://hrcak.srce.hr/index.php?show=clanak&id_clanak_jezik=137830&lang=en

solution_essays/se_The_Art_and_Science_of_Pressure%20Distribution.pdf