By Harry T. Loftin, Jr.

Setting optimum pressures on the pretension and threaded rolls of tow-opening machines is critical to the successful preparation of Celanese® Acetate tow for cigarette filter rodmaking. The band of acetate fibers (tow) must be processed to deregister, or open, the fiber crimp. Incorrect roll pressure settings on the threaded-roll tow-opening system can adversely affect the process and in turn adversely affect the resultant filter rod quality.

Figure 1 Pretension Roll Set

There are two types of pressure rolls on the tow opener. The pretension rolls that prepare the tow for opening by the threaded roll(s) consists of a smooth steel roll paired with a hard rubber roll (Figure 1). The threaded roll(s) may be either a single set of rolls or two sets of rolls in tandem, depending on the model of the equipment. A threaded-roll set consists of a steel roll with a threaded surface paired with a hard rubber roll (Figure 2).

Figure 2 Threaded Roll Set

Pressure-indicating films work by virtue of microspheres, coated onto the film substrate, that rupture at various predetermined stress levels. On the application of force, the film develops a permanent and irreversible color tone that identifies how much pressure the film has been exposed to. The color intensity of the exposed film is directly related to the amount of pressure that has been applied to it. The greater the pressure, the more intense the color. By visually comparing the resultant film with a set of color standards, the operator can closely estimate actual roll contact pressure.

The film indicates both the magnitude and distribution of the contact pressure along the nip rolls, allowing the operator to adjust the individual roll pressures to the required operating level. After the operator has made an impression between the set of rolls (nip impression), the film sample can be evaluated to determine whether the rubber rolls are unevenly worn or require replacement.

The method as described above provides a quick, easy “litmus test” for approximating roll pressure without additional equipment and with little downtime. Pressure readings are accurate within ±4%. For those users who require greater accuracy than can be obtained by a simple visual comparison, a sophisticated Windows-based analysis system may be used to read and evaluate the pressure film samples, as described later in this article under Precision Pressure Measurement.

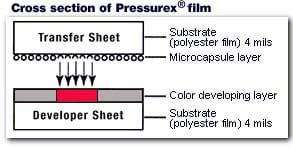

PRINCIPLE OF OPERATION The pressure indicating film used is Pressurex® Super-Low Pressure Film1. The system consists of two types of film: A transfer sheet containing a layer of microencapsulated color-forming material, and a developer film containing a layer of color-developing material, as shown in Fig. 3.

Figure 3 Cross-section of Pressurex® pressure indicating film system and its operating principle.

The two film components are fed slowly through the nip of the rolls in a sandwich arrangement. The matte (coated) sides of the films must contact each other to effect a color change. As pressure is applied, some of the microcapsules on the transfer sheet are broken, releasing a dye precursor that reacts with the developer sheet. Through control of their size and wall thickness, the microcapsules are calibrated to rupture at specific pressure levels, producing a color density that correlates directly with pressure applied. The film is then matched visually with a color calibration chart for approximate determination of roll pressure.

Measurement Procedure

- Without allowing the film components to touch, cut the Pressurex transfer and developer sheets into 2-inch by 5-inch strips. It is imperative that the films be prepared separately to prevent premature color development.

- Remove the acetate tow from the tow-opening system.

- Reduce the speed of the unit to the lowest possible setting. Nondriven rolls may be turned manually.

- Apply pressure to the nip. The nip must be engaged before the film is introduced to the rolls.

- Sandwich the transfer and developer sheets together with the matte sides contacting each other.

- Carefully insert the 2-inch edge of the films into the center of the rotating rolls (Figure 4) and draw the film through the nip.

- Immediately separate the films to prevent further color change due to handling. (The color is sufficiently stable to allow archiving after the films are separated.)

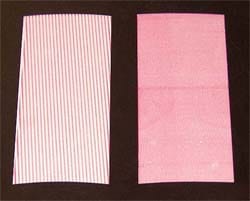

- Visually compare the film impression (Figure 5) with the appropriate color-density chart to determine the pressure of the nip rolls. Note: A color-density chart is available from Celanese Acetate.

Figure 4 Film strip passing through the threaded roll set.

Figure 5 – Figure 5 Exposed film strips from the threaded roll set (left) and the pretension roll set (right).

The readings represent the actual pressure on the rolls, not the gage pressure. A gage reading can vary depending on the type of roll loading system employed. For example, the gages might display 1.5 bar when the actual pressure exerted on the rolls is only 0.75 bar. Again, note that this procedure does not allow determination of exact pressure levels between the nip rolls when performed with the visual method described. A user can expect to obtain accuracy of ±15% of actual psi value if the film is visually compared with the color calibration chart.

Precise Roll Pressure Measurement

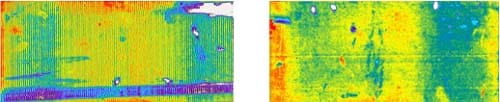

For those who require more accurate nip-roll pressure measurements, the Topaq Advanced Imaging System2 is a Windows-based system that produces high-resolution, color-calibrated images showing both the magnitude and distribution of pressure forces captured on Pressurex pressure-indicating film. The system can be used to obtain tactile pressure measurements for nip rolls or for any other two contacting surfaces. The exposed developer sheet is scanned into the system and the computer queries the user for input variables. It then generates full-color pressure maps (Figure 6) with relevant statistical data. The Topaq system is accurate to within ±1%, w

hich is highly precise for tactile pressure measurement.

Figure 6 – Topaq pressure maps from the threaded roll set (left) and pretension roll set (right).

Harry T. Loftin, Jr., is a senior R&D engineer, Product Development, at the Celanese Acetate headquarters in Charlotte, North Carolina, USA.

1 – The films are available from Sensor Products Inc., 188 Route 10, East Hanover, NJ 07936, Tel. 973-884-1755, Fax 973-884-1699, Internet: www.sensorprod.com. Pressurex Super-Low Pressure Film is useful to measure pressures ranging from 70 to 350 psi. Other films are available with pressure sensitivities ranging from 28 to 18,000 psi.

2 – Available from Sensor Products Inc.