Article: MachineDesign.com

The Leonardo Museum, Salt Lake City, a science, technology, and art center, is engaging students� bodies as well as their minds with a portable surface-pressure-body-mapping exhibit. In the �Under Pressure� exhibit, visitors sit on a pressure pad and see how contact between the body and an object can create pressure points and strain.

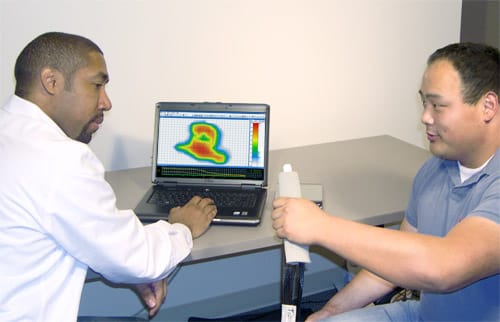

A traveling museum exhibit uses Tactilus® from Sensor Products Inc.

to teach students about pressure. Surface-pressure-body mapping has applications in a

wide range of consumer products from bottles to mattresses.

The exhibit, designed by Joe Andrade, professor of bioengineering at the University of Utah, is traveling to schools and libraries until the museum opens permanently next April. The exhibit uses a Tactilus® Body Mapping Pressure System, donated by Sensor Products Inc., Madison, N.J. The Society of Plastics Engineers and the Utah Science Center fund the traveling kiosk. �The kids and adults really love the exhibit,� says Andrade. �They chuckle and can�t wait to sit on the pressure pad to see their body maps. Meanwhile, they are learning about science and technology.�

In pressure-body mapping, sensors measure the forces exerted by a body on a surface and convert the data into colorcoded pressure maps of the contact surface. Designers use the information to modify products for more even pressure distributions.

Reducing high-pressure areas makes products more comfortable, ergonomic, and efficient. The technology has been used to customize mattresses for different body types, make plastic tubes and bottles easier to squeeze, and correct golfers� stances and swings.

Pressure-body mapping can also trim production cost. A major toothpaste manufacturer, for example, used Tactilus® to more-closely pinpoint the forces customers apply when dispensing toothpaste. Focus group members tested prototype packaging by squeezing all the toothpaste out of a tube. Tactilus® measured the squeeze pressure along the tube, including the forces involved in rolling the tube up to extract the last few dabs of toothpaste.

Surface pressure body mapping helped a toothpaste manufacturer pinpoint the forces

applied to its packaging. Designers were able to switch to a less costly material.

The tests gave designers the first quantitative measure of squeezing effort. Using the data, the company found a less-costly packaging material that still performs to consumer expectations. MD