Attila Kis*, Ferenc Kovács*, and Péter Szolgay*

Pázmány Péter Catholic University,

Information Technology Department,

Piarista köz 1, H-1052 Budapest, Hungary

*Analogic and Neural Computing Systems Laboratory,

Computer and Automation Institute,

Hungarian Academy of Sciences,

P.O.B 63, H-1502, Budapest, Hungary

e-mail: [akis,szolgay]@sztaki.hu, [email protected]

Abstract

An analogic CNN algorithm was developed and tested in order to detect failures such as blobs, bumps and disruption on textile in real time by using an experimental system with pressure sensory arrays Tactilus®, a CCD camera and the cellular visual microprocessor development system, Aladdin Pro. The tactile sensory system is focused on the suspicious areas by the optical input. The places in question will be checked carefully by the above tactile sensory system working with an analogic algorithm. Fiber breaks and knots are the typical errors to be detected.

Introduction

In course of the machine inspection of textile fabrics the characterization of the defects and the high data rate constitute the two major obstacles. Faults in textiles have traditionally been detected by vision unit inspection [1,2]. These systems are reliable, though their accuracy is not high [3]. For the characterization of the defects tactile inspection, information gathering about the physical aspects of the textile are adequate. Therefore, industrial vision units fused with tactile units are of strategic interest for the textile industry as they provide a base for a system achieving a high degree of accuracy in textile inspection.

The paper describes the software core of a system designed for fabric inspection based on combining some simple optical and tactile image-processing operations, as well as the efficiency of the software core in detecting the usual textile defects. The prerequisites of the over all system are then discussed analytically, as well as the limitations and the restrictions due to the nature of the problem. The software algorithm and the evaluation of the first results are also presented in detail.

This system consists of two major parts: vision and the tactile inspection unit. In this contribution we focus on the tactile fault detector and recognition system, since the visual unit was presented in details in a previous paper [4]. We will present snapshots recorded on the pressure field of tactile actions investigating the surface of a textile and preprocess by a CNN-UM [5-6].

In Section 2 the experimental system is described. The analysis of the tactile fault detecting process is given in Section 3, and based on the experiments, some concluding remarks are given in Section 4.

2. An Experimental System For Detecting Faults On Textiles

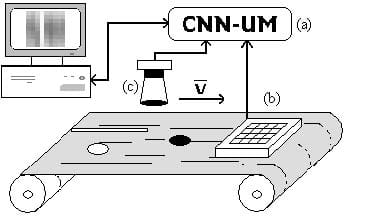

The textile rolls at a known and adjustable speed, usually about 600mm per second. The visual unit search for patches or blooms, and provides the coordinates of the flaws. The tactile unit explores the areas only indicated by the vision unit, saving a lot of time. The main parts of the system are presented in Figure 1.

Figure 1: The main parts of the system: (a)AceBox 4K, (b)Tactilus®,(c) CCD camera

The signals are processed by the AceBox [7]. This unit processes the tactile images. Due to the system’s being designed for real-time operation, we need a fast response from the processing unit, which is well accomplished by the CNN-UM. Analogic algorithm may be especially useful when large amount of images (frames/sec) have to be processed. In our case the pressure field is coded in grayscale images.

For the sensory array Tactilus® tactile system is used [8], available commercially.

The PC is only used for display the events and it makes the connection between the sensor part and Aladdin Pro.

2.1. Pressure sensing trough Tactilus®

Tactilus® is an electronic tactile force and pressure-indicating sensor, connected to a PC via a USB port. The reason why we use capacitor-based sensors is that they are more robust and resistant to changes in operating temperature than the two other, most common approaches, resistor-based and piezoelectric pressure sensors. The sensors are of linear responses, and low hysteresis. Performance is less likely to degrade over time.

Tactilus® allows precisely monitoring how force is dispersed between any two contacting or mating surfaces in real-time while the event occurs. The system includes a 50mm x 50mm palm sensor with 2.5 mm spatial resolution (21×21 tuxels) and five finger sensors, 13mm x 13mm each, 1.5 mm spatial resolution (9×9 tuxels). One tuxel is equal to one sensor point in a sensor array. The query rate of this system is up to 60,000 sensor- points/sec. The optimal range of pressure for sensor pads is 0-1 atm, accuracy ±10%.

2.2. Interface of the sensory part to Aladdin Pro with 64*64 CNN-UM

Aladdin Pro System provides a common framework for developing analogic CNN algorithms. The algorithms can be run on software simulators or a 64*64 CNN-UM analog VLSI chip [9]. The ACE4k is the platform containing a CNN-UM chip built in a board type PC104. The platform is connected to the host PC by a PCI bus interface, and provides the 64*64 CNN-UM a fast capability for loading data up-and-down.

3. Flowchart of the core algorithm

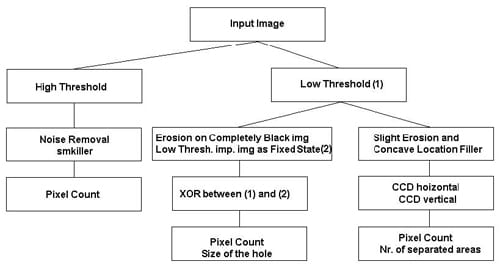

The algorithm detects three major kinds of faults: bumps, holes and split or disruption on the textile. The flowchart of the algorithm is given in Figure 2.

Figure 2: The flowchart of the algorithm

As the first step with a less sensitive, high threshold template, we can extract the regions where the pressure is above the usual rate. In a usual case it is possible to have high rate pressure, manifesting on a small, randomly occurring areas only, which are due to the noise and irregularities in the textile. The high-pressure area exceeding the usual means, that there is a bump on the surface.

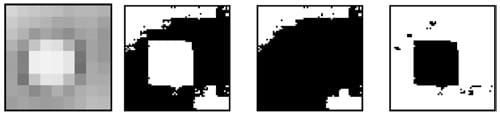

In order to detect holes (Fig. 3.a.) and splits, we need a sensitive, low threshold, since on these regions the pressure is lower than the average. (Fig. 3.b.)

Figure 3: (a) The original hole, (b) threshold, (c) contour, (d) the hole

By using this image as a fixed state on a completely black image, by a propagating erosion template, the shape of the pressured area without any hole (Fig 3.c.) is resulted. Making an XOR logical operation between the original, thresholded image and the erased black patch, we will get the area of the hole (Fig 3.d). The reason we need this algorithm, instead of simply inverting the input image, is that due to irregularities, we cannot apply a uniform pressure to on whole sensory array, especially at the borders. By counting the black pixels on the output image, we can tell the size of the hole.

Figure 4: (a) The original tactile image, (b) threshold, (c) erosion and concave location filer, (d) horizontal CCD, (e) vertical CCD

If there is a disruption on the textile (Fig. 4.a), after applying the low threshold, we get two areas separated (Fig. 4.b). By applying erosion and filling the concave locations, the above areas will become convex as a result (Fig. 4.c). This is important because, this way, with a horizontal CCD (Fig. 4.d) and a vertical CCD (Fig. 4.e) template, there will be only two pixels on the output image, according to the to number of the areas.

4. Limitations and conclusions

A method for detecting faults on textile has been presented. It is being used as a part of a whole inspection system for quality control in textile industry. The method has proved to be robust in practice, working perfectly when applied to textiles with different patterns, complexities and colors. The real-time requirements of the task have been adequately met. The operations carried out here are very fast, of the order of a 10 to 20 processed frames per second.

Acknowledgment

The authors acknowledge the support received from the Hungarian Research and Development Programme, TeleSense project Grant (NKFP) No. 035/02/2001.

REFERENCES

1. A. Bodnarova: “Textile Flaw Detection Using Optimal Gabor Filters”. Proceedings of the International Conference on Pattern Recognition (ICPR’00)-Volume 4, p.4799, September 03-08, 2000

2. C. Bahlmann, G. Heidemann, H. Ritter: “Artificial Neural Networks for Automated Quality Control of Textile Seams”. Pattern Recognition, volume 32, number 6, pp. 1049–1060, June 1999

3. R. Franke: “Scattered Data Interpolation: Tests of Some Methods”, Mathematics of Computation, Vol.38, No. 157, pp. 181−200, 1982

4. L. O. Chua, T. Roska, T. Kozek and Á. Zarándy, “The CNN paradigm – a short tutorial in Cellular Neural Networks” (eds. T. Roska and J. Vandewalle), John Wiley & Sons, New York, 1993

5. L. O. Chua, L. Yang: “Cellular Neural Networks: Theory”, in IEEE Transactions on Circuits and Systems, Vol. 35, pp. 1257–1272., 1988

6. T. Roska, L. O. Chua: “The CNN Universal Machine – an Analogic Array Computer”. IEEE Trans. on Circuits and Systems II: Analog and Digital Signal Processing Vol. 40, No. 3, pp. 163-173, 1993

7. Aladdin Pro System, Analogic Computers, 2002, www.analogic-computers.com

8. Sensor Products, Tactilus Real-Time Tactile Pressure Measurement, Madison NJ, www.sensorprod.com

9. S. Espejo, R. Dominguez-Castro, G. Linan, A. Rodriguez-Vázquez: “A 64×64 CNN Universal Chip with Analog and Digital I/O”, Proceedings of 5th IEEE International Conference on Electronics, Circuits and Systems, (ICECS’98), pp. 203-206, Lisboa, 1998

10. A. Kis, N. Bottka, F. Kovács, and P. Szolgay: ”Elementary CNN Algorithms and an Experimental System for Typical Tactile Actions”, Proc. of IEEE ECCTD03, pp I-413- I-416, Krakow, 2003