S. PAUL SINGH1,*, JAY SINGH2 and YOUNG PAEK3

1Professor, School ofPackaging, Michigan State University, East Lansing, Michigan, USA

2Associate Professor, Industrial Technology, Cal Poly State University, San Luis Obispo, CA

3Graduate Assistant, School ofPackaging, Michigan State University, East Lansing, Michigan, USA

Abstract

Pressurex�, atactile pressure sensor film which is manufactured by Sensor Product Inc. (East Hanover, NJ, USA), is one ofthe emerging materials that is convenient for measurements of the strength of pressure and pressure distribution profile between two contacting surfaces without any instrumentation. It immediately reveals impact distribution and magnitude based on intensity and dispersion of color. The intensity of this color is proportional to the amount of force applied allowing the user to actually quantify the stress characteristics across the impact surface. The objective of this paper was to examine free fall drop test results using six different ranges of sensor films with two cushion materials as backing (plastic corrugated and foamed polystyrene sheets). Throughout this study, the dispersion of force and pressure strength through the different free fall drop heights was evaluated using these materials. The best film and cushion material to predict drop height was selected using visual inspection of the imprinted surface based on the magnitude of the color and intensity on the film. A correlation was developed based on the area and diameter of the imprinted surface.

1.0 Introduction

In the journey through the supply chain, all packages are expected to protect the product from various static and dynamic hazards they experience such as drops, impacts, vibration, compression and climatic. Damage during handling (loading, unloading a.rid sorting) is commonly observed. Thus for a safe product delivery a functional and efficient cushioning material that can isolate most ofthe forces from reaching the product is usually desired. In addition to both the federal and state requirements there are several trade associations and professional organizations that through their membership develop packaging test methods that manufacturers can use for a given application. The associations and organizations most involved in developing the distribution packaging standards are International Standards Organization (ISO), American Society of Testing and Materials International (ASTM) and International Safe Transit Association (ISTA). Although these standards are adequate in replicating the distribution hazards, they are unable to provide visual evidence ofthe amount ofpressure experienced, during say a drop, between the product and the package.

Pressurex�, a tactile pressure sensor film which is manufactured by Sensor Products Inc. (East Hanover, NJ, USA), provides a convenient tool to measure the strength of the pressure and pressure distribution profile between two contacting surfaces without any instrumentation. It immediately reveals impact distribution and magnitude by intensity and dispersion of color which is proportional to the amount of force applied allowing the user to actually quantify the stress characteristics across the surface [1]. That is to say, greater pressure has higher intensity imprint on the film. While conventional lab test instruments commonly used, such as triaxial accelerometers, are expensive and difficult to measure impact profile during transportation, these sensor films can easily be inserted between product and package to determine the impact levels during an impact, economically. There are no studies done to evaluate performance and accuracy of sensor films as an alternative of the conventional impact and pressure test method for replication of impacts experienced by packages in distribution.

For this study six different types of pressure sensitive films; Ultra Low, Super Low, Low, Medium, High, and Super High were obtained from Sensor Products Inc. These films were backed with two different types of materials and placed under spherical shaped weights of 3.6 kg and 6.8 kg (81bs and 15lbs) and approximately 200 mm (7.90 in) in diameter. The setup was then placed in corrugated boxes. The test packages were then allowed to fall freely from different heights. Observations were then made on the film for distribution and magnitude of the force experienced.

The objective ofthis research was to examine free fall drop test results using six different types of pressure films with two cushion materials, corrugated plastic and foamed polystyrene sheets. Throughout this study, the dispersion of force and pressure strengths through the different free fall drop heights was evaluated using these materials. The best film and cushion material to predict drop height was selected using visual inspection of the imprinted surface based on the magnitude of the color and intensity on the film. A correlation was then developed based on the area and diameter of the imprinted surface.

2.0 Experimental Design and Materials

2.1 Pressure Indicating Sensor Films

Sensor Product Incorporated’s tactile pressure indicating sensor film (Pressurex�) is marketed as a unique, affordable and easy to use tool for revealing the distribution and magnitude of pressure between any contacting, mating or impacting surfaces [1]. The materials were initially developed for the National Aeronautical and Space Administration (NASA) for aerospace applications. Pressurex� is a mylar film containing a layer of microcapsules that rupture producing an instantaneous and permanent high resolution “topographical” image of pressure variation across a contact area upon the application of force [1].

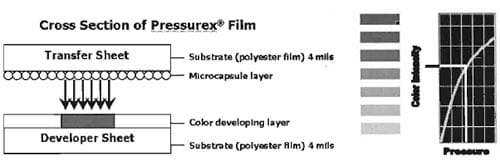

Pressurex� is extremely thin (0.10, 0.20 and 0.51 mm or 4, 8 and 20 mils) and provides a suitable alternative for strain gauges and load cells. It can function between 5�C to 35�C (41�F to 95�F) and 20% to 90% relative humidity ranges. With a shelf life of 1 year, Pressurex� provides �1O% visual accuracy and �2% accuracy utilizing optional optical measurement systems [1]. Application areas for this product include aerospace, automotive, electronics, medical, packaging, plastics and printing/papermaking. Figure 1 shows the structure and functionality of this material.

Figure 1. Cross section of Pressurex� film and color intensity scale.

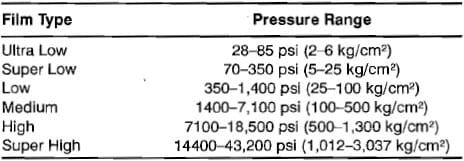

Table 1. Sensitivities of Various Pressurex� Films.

This product is available for a

wide range of pressures (1.97-3,037.26 kg/cm2 or 28-43,200 psi) as shown in Table 1.

2.2 Cushioned Backing Material

The two types of cushioned backing materials used in the study were single wall, profile extruded polypropylene corrugated sheets weighing approximately 1.07 kg/m2 (220 lbs/1,OOO ft2) and extruded expanded polystyrene foam panels measuring 7 mm (0.28 in) in thickness.

2.3 Corrugated Boxes

Regular slotted containers (RSC) made with single-wall C-flute corrugated board were used in this study. The dimension of the box was 219 x 219 x 241 mm (8.63 x 8.63 x 9.5 in).

2.4 Weighted Spheres

For the test product, two different weighted spheres (3.6 and 6.8 kg) measuring 200 mm (7.9 in) in diameter were used. The spherical weights were selected because of their complex shape (sphere versus cube) and because it produced a shape dependent imprint as a function of impact energy (drop height).

2.5 Test Setup

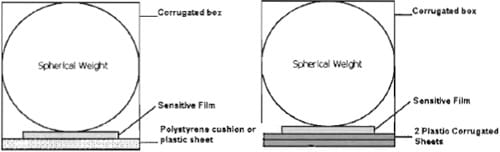

Two types of cushioning materials used as backing for the Pressurex� film were plastic corrugated sheets and expanded polystyrene (EPS) foam sheets. Both were approximately 7 mm (0.28 in) thick. The different types ofpressure sensitive film were applied to the backing material.

Figure 2. Test package configurations.

The spherical weight was placed on the pressure sensitive film and placed inside a single wall regular slotted container (RSC) style box. The test package arrangement is shown in Figure 2. The test packages were then subjected to drop heights from expected drop levels as recommended by ASTM D4169 [2].

2.6 Test Conditions

All samples were conditioned at a temperature of 23�C (73.4OF) and 50% relative humidity for at least 24 hours in accordance with the atmospheric conditioning, which is recommended in ASTM D 4332 [3].

2.7 Test Procedure

Eighteen test boxes (three replicates for each of the six types of pressure sensitive films) were made from single-wall C-flute corrugated board to perform drop tests using the pressure sensitive films to observe correlation between the size ofthe imprint and drop height. The main objective of the study was to determine ifthis film can be used as a sensor to determine drop height levels inside packages based on the color and size of imprint. The correlation was based on the major diameter of the imprint or the total imprint area versus the drop height for the various combinations. Since the package weighed less than 9 kg (20 lbs), drop heights between 0.45 to 1.21 m (18 and 48 inches) were selected as recommended in ASTM D4169 for the three assurance level extremes [2]. Testing was conducted in the following three phases:

- During the initial phase to evaluate the optimum combination that provided the best visual results, drop heights of 0.61 ,0.76 and 0.91 m (24, 30 and 36 in) were used for all six grades of sensor films with the two types of backing materials. The imprints were visually examined.

- For phase two, drop heights of 0.45, 0.66, 0.86 and 1.22m (18,26,34, and 48 in) were used to further narrow down the qualification for the optimum combinations using the best results from phase one.

- Having found the best combinations from phase two testing, further testing was conducted using the optimum combinations of sensor film, backing material and spherical weights. Drop heights of 0.61, 0.76 and 0.91 m (24,30 and 36 in) were used to quantify the pressure imprints on the sensor films and the derivation of the regression relationships to predict drop heights.

3.0 Results and Discussion

3.1 Phase I: Comparison of the Performance of Different Films

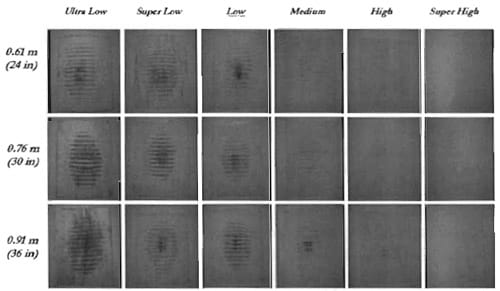

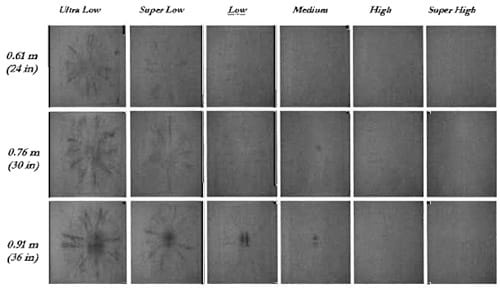

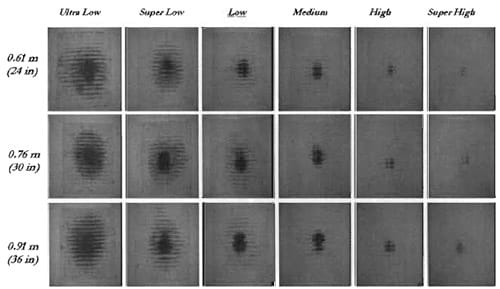

Using the two different packages (Figure 2), six different pressure sensitive films were tested to select the most adequate film to represent commonly occurring package drop heights. The drop heights used were 0.61, 0.76 and 0.91 m (24, 30 and 36 in) for the initial phase. The results for the first phase are shown in Figures 3, 4, and 5.

Figure 3. Results of drops using 3.6 kg (8lb) spherical weight and plastic corrugated backing.

Figure 4. Results of drops using 3.6 kg (8lb) spherical weight and EPS backing.

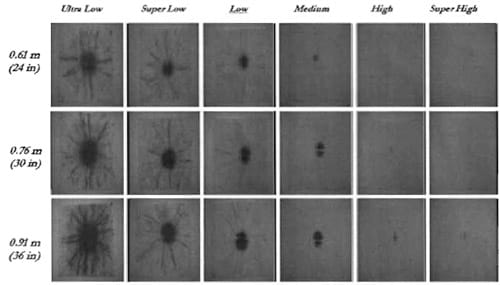

As shown in the results in Figures 3 through 6, Ultra Low and Super Low sensor films with 6.8 kg (15 lb) and soft backing materials showed obvious differences in the intensity of color for the pressure marks on the film as a function of the drop height. On the other hand, there were less significant differences between the intensity on the imprint when Low, Medium, High, Super high films were used. In the case of High and Super High films, it was difficult to examine the magnitude and intensity of color on the film. These differences were caused by the inherent characteristic of the films. These films were designed for high pressure environments and the impacts observed by the sensor films in this research may not have caused pressure to exceed the threshold point of the films.

Figure 5. Results of drops using 6.8 kg (15lb) spherical weight and plastic corrugated backing.

Figure 6. Results of drops using 6.8 kg (15lb) spherical weight and EPS backing.

In terms of backing materials, extruded polystyrene foam panels showed clear and visible color difference as compared to the plastic corrugated sheet. In addition, the polystyrene sheet was better than plastic corrugated sheet to calculate the area and diameter of the pressure imprint on the films.

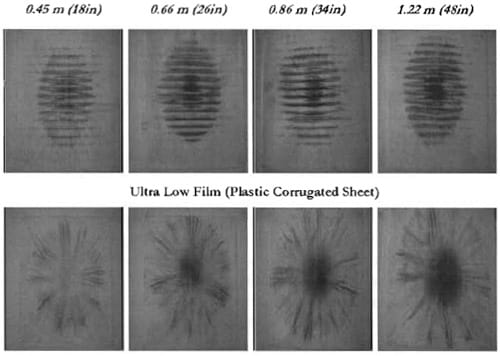

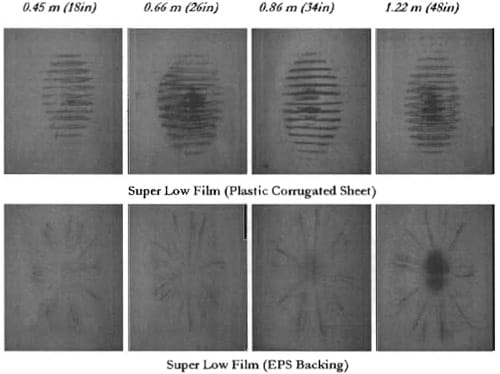

3.2 Phase II: Comparison of the Performance of Selected Combinations

Since not all the results from Phase I were very easy to interpret, this phase helped isolate the optimum combinations of sensor film and backing materials for further investigation. Ultra Low and Super Low sensor films with both the plastic corrugated sheets and EPS foam backing were further tested using the 3.6 kg (8Ib) spherical weight from four different drop heights of 0.45, 0.66, 0.86 and 1.22 m (18, 26, 34, and 48 in). The results are shown in Figures 7 and 8.

Figure 7. Results of Phase II testing for ultra low sensor film.

Figure 8. Results of Phase II testing for super low sensor film.

3.3 Phase III: Quantification of Pressure Imprints and Derivation of Regression Relationships

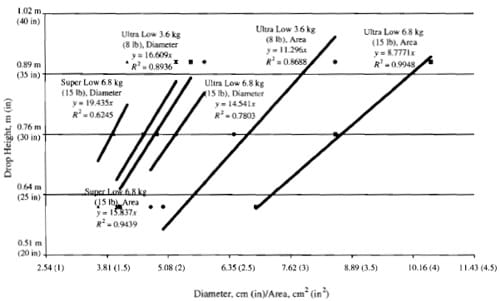

Based on the results from the first and second phase testing, the Ultra Low film in conjunction with the two spherical weights and the Super Low film in conjunction with the 6.8 kg (15 lb) spherical weight were used to repeat the testing from three different drop heights, 0.61, 0.76 and 0.91 m (24,30 and 36 in). The linear regression plots for the more prominent combinations of sensor film and backing materials are presented in Figure 9.

For the application of the sensor film to measure and predict dynamic shock values experienced during drops, a quantification of the pressure imprint on the film w

as used to develop linear regression relationships with the actual drop heights. In addition, the major objective of this research was to evaluate the feasibility ofthe sensor films as a cheaper substitute for higher cost dynamic drop testers. Based on the tests, these sensor films provide a simplermethod of measuring and predicting package drops by evaluating the strength and pressure distribution profiles between two contacting surfaces.

Since the pressure imprints on the films are circular in shape (function of impact surface), the diameter and the subsequent area of the pressure mark were good candidates for the representation of the actual drop height. For this reason,the diameter and the area of the pressure imprints on the film were tried as the indicators of the actual drop heights. Five replicates of the diameters of the pressure mark were measured for each film with specific drop height. Thereafter, the approximate area of the pressure marks was calculated.

Figure 9. Linear regression relationships for Phase III testing.

The average diameters and areas were plotted with the actual drop height for each film. Each data set was analyzed with linear regression method. As shown in Figure 9, the R2 values between the area and the drop height, which varies between 0.8688 and 0.9948, are much higher than those between the diameter and the drop height, which vary between 0.6245 and 0.8936. This means that area of imprint on the film was a better indicator of the actual drop height and could be used to predict actual drop heights.

For the R2 values of the correlation between imprint area and the drop height, the result of the Ultra Low film showed better performance than Super Low film. The R2 values for the Ultra Low film was 0.9948 and that for Super Low film was 0.9439 for the 6.8 kg (15Ib) weight. These results show that the measurement of the imprint area using Ultra Low film could be a better indicator of the drop heights.

This method can now be used with other shaped objects and actual products. Shippers can mount the pressure sensitive film on a foam backing and apply to the bottom surface inside a package. They can then calibrate the shaped object and imprint area as a function of drop height. Post damage analysis would require observing the film and measuring the size of imprinted area to predict safe or severe handling.

4.0 Conclusions

- Ultra Low sensor film was the best to predict actual drops and associated heights and extruded polystyrene foam sheet was the best backing material based on this study.

- While comparing the cushion materials, extruded polystyrene sheet was better in calculating the magnitude of area, color and clarity to evaluate the dispersion of pressure strength on the film.

- The results showed that the pressure sensitive film is a useful method to predict drop height without any expensive instrumentation and can be successfully used as an indicator of the drop height in various distribution environments. These films can be used in shipments of expensive products to show evidence of severe impacts in case damage occurs.

References

- Sensor Product Inc. (2004) “Pressurex”, Available at https://www.sensorprod.com/pressurex.html, accessed June 14, 2009.

- ASTM D4169 -08 (2008) Standard Practice for Performance Testing of Shipping Containers and Systems, Vol. 15.10, American Society of Testing and Materials, West Conshohocken, PA, USA, 2007.

- ASTM 04332-01(2006), Standard Practice for Conditioning Containers, Packages, or Packaging Components for Testing, Vol. 15.10, American Society ofTesting and Materials, West Conshohocken, PA, USA, 2007.