Article: Tobacco Reporter

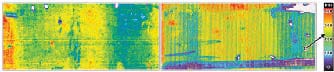

Topaq® pressure analysis of the threaded roll set and the pretension roll set

In the current economic climate it is more important than ever that the raw materials used to make a product be processed in the most effective and efficient manner possible. This economic reality also applies to converting acetate tow into cigarette filters. To accurately and cost effectively process acetate tow into cigarette filters, precise pressure measurement between the contacting rollers (the nip) is essential. Pressure measurement at the nip is easily and cost effectively performed with pressure indicating film, which improves filter quality while reducing material utilizations. Sensor Products of New Jersey, USA, offers such a film—Pressurex®.

Acetate tow is produced and packaged in a very compact form to facilitate handling and shipping. The tow band must then be processed to increase its bulk before being made into cigarette filters. The average acetate tow band consists of 12,000 tightly packed individual fibers. These fibers are very small and must be handled carefully during processing. The fibers are so minute that one fiber rolled out to 9,000 meters (approximately 5.6 miles) weighs as much as five small paper clips.

Sufficient pressure application at the nip during tow processing is essential. If the nip roll pressure is insufficient, the tow will slip through the system and fail to process properly. Improperly processed tow will not efficiently fill the cigarette filter and will require additional acetate tow to be added to the filter. This additional material adds weight to the final filter, which, in turn, costs more money and lowers efficiency.

The tow moves through processing from right to left and the roller sets consisting of one steel roll and one rubber roll hold the tow firmly via pressure. The roller sets operate at different speeds creating a “stretching” action that expands or “opens” the tow. This creates an efficient and cost-effective cigarette filter.

While there are air pressure gauges on the processor with standardized settings, they do not ensure sufficient consistent pressure between rollers. Pressurex® pressure indicating sensor film measures the force between the rolls easily and without damaging the rolls. Strain gauges and load cells are time consuming and difficult to use and they may damage the rollers during the measurement process.

Simply place the pressure indicating sensor film between the tow processor nip rolls, apply pressure and remove it. The film reveals the pressure distribution profile that occurred between the two rollers. (Note: Do not impact load the film. Close the rolls and slowly feed the film through.)

Pressurex® is a Mylar-based film that contains a layer of tiny microcapsules. The application of force upon the film causes the microcapsules to rupture and the film to instantaneously and permanently change color directly proportional to the actual pressure applied. Precise pressure magnitude is easily determined by comparing color variation results to a color correlation chart.

The film is extremely thin (4-8 mils), which enables it to conform to different types of curved surfaces. It works just as effectively on the threaded roll on the tow processing unit as the smaller smooth nip rolls at the beginning of the tow “opening” process. Additional force analysis of the film, which renders high resolution color-calibrated pressure maps, is also available from Sensor Products.