Article: Nonwovens Report International

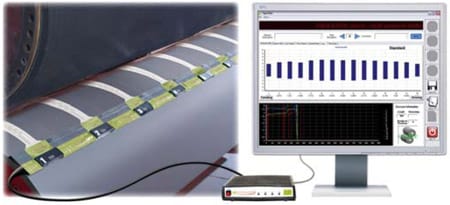

Sigma-Nip®, positioned on a roller and linked to a computer, provides real time nip analysis

Dupont, Metso Paper and PGI are among leading companies who have recently purchased Sigma-Nip®, an electronic nip analysis system which quickly and cost effectively measures roller profiles and diagnoses roll alignment.

By recording nip width via sensors, it makes time-consuming and inexact tools such as carbon paper and embossed foils obsolete, according to its manufacturer, Sensor Products, based in Madison, New Jersey, USA.

When Sigma-Nip® is used, loading problems, skewing and crown deficiencies are quickly exposed. It consists of a chain of sensor elements and Windows-based software. The latest sensors have been improved to withstand repeated high pressures and temperatures as well as routine exposure to grease and solvents. When placed between two contacting rollers, the sensors capture data and ultimately record and assimilate nip width readings on a laptop while it is being viewed. Adjustments to rollers are made in real time while the sensors are in the closed, (non-rotating) nip. Easy-to-interpret statistical data and graphical displays � transmitted via wireless or through a USB port � update continuously as technicians perform their tests and adjustments.

Taking only minutes to deploy across the roller face by a single operator, Sigma-Nip® is useful for ongoing maintenance, as well as during equipment setups and shutdowns. As a quality control tool, its evenly-loaded roller sets are much less likely to cause web breaks and down time. It also improves web control and print quality by reducing uneven web pulling, which can lead to sheet walking, wrinkles, jams and mis-registration.

�Sigma-Nip® has come a long way from concept to being a reliable, easy-to-use nip profile measuring tool,� says Mike Stoltz of Metso Paper. �Being able to save and review the entire real-time data from nip closing to nip opening is extremely useful, but the ability to correlate accurate nip width data to roll deflection is an exceptional benefit.�

Sigma-Nip® is designed for maximum versatility. The system is portable and comes with its own carrying case. Depending on the number of sensors ordered, the same sensor chain can be used to measure different sized rolls. Nip widths from 00.38cm to 22.9cm can be measured, and pressures from 2.8 kg/cm² to 3,000 211 kg/cm² can be withstood. Large pulp and paper rolls, small converting rolls and calender stacks are all potentially measurable by Sigma Nip® and face lengths of 90cm to 1,125cm can be accommodated.

Minimal computer knowledge or training is needed since the system prompts users through the few steps needed for installation and set up. Software enhancements include a comparison mode, where up to three nip width readings can be viewed simultaneously, and an alignment tool, which instantly draws a line to indicate nip width variations.

The New Sigma-Nip Mini

The latest introduction from Sensor Products is the Mini Sigma-Nip® for measuring nip widths of rolls with circumferences smaller than 51cm. With this unit, large, bone-hard rolls with narrow contact areas can also be characterised by an electronic system for the first time.

In Mini Sigma-Nip®, the 168 microscopic sensor points that comprise each finger are densely packed within an 8.4cm active sensing area. This yields nip measurements with 2.5 times the resolution of the larger Sigma-Nip®, the company says.