Article: Industrial Products Finder (India)

Sensing area is very compact for high resolution measurement.

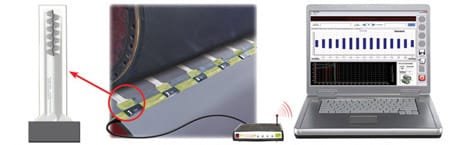

Mini Sigma-Nip® positioned on a roller set, and transmitting to a laptop, provides real-time nip analysis.

Roll alignment for converting and printing is now fast, cost-effective, and precise technological development yields extremely high resolution for measuring smaller nips.

Mini Sigma-Nip® is an electronic nip analysis system introduced by Sensor Products Inc., for converting and printing. It measures roller profiles and diagnoses roll alignment with unprecedented speed, cost-effectiveness, and accuracy. The technology for Mini Sigma-Nip derive s from Sigma-Nip®, which characterizes roller profiles for larger rolls. Mini Sigma-Nip®, which measures nip widths of rolls with circumferences smaller than 20� (51cm), can also diagnose and measure larger hard rolls that have narrow contact upon closing.

In Mini Sigma-Nip®, the 168 microscopic sensor points that comprise each finger are densely packed within a 3.3 in. (8.4 cm) active sensing area. The sensors capture data and record nip width readings while being viewed on a laptop or computer that has been connected through wireless or USB. Adjustments to load are made in real time while the sensors are in the closed, (non-rotating) nip. Problems with alignment, skewing, and crown deficiencies are quickly exposed.

Mini Sigma-Nip® is designed for maximum versatility. The system is portable and, depending on the number of sensors ordered, the same sensor chain can be used to measure different sized rolls. It is extremely useful for continuous maintenance, as well as during equipment setup and shutdown. Data that has been stored can be easily reviewed. Web control is improved as evenly loaded roller sets are much less likely to cause web breaks and costly down time. Uneven material pulling, sheet walking, wrinkles, jams and print misregistration are greatly reduced.

Among other features, the software includes a Comparison Mode, where up to three nip width readings can be viewed simultaneously, and an Alignment Tool, which instantly draws a line to indicate nip width variations. Minimal computer knowledge or training is needed since the system prompts the user through the few steps needed for installation and set up. The various nip product solutions from Sensor Products Inc., can be viewed online at www.sensorprod.com/minisigmanip