A Tactile Stress Sensor is a material or device that measures stress-inducing forces between two surfaces in contact with one another. Generally, temperature and vibration are the major stress inducing factors. However, the connections of plastic and composite materials are also susceptible to the loss of clamp load due to the viscoelastic characteristics of these materials. This has caused concern in the US Navy, which is interested in developing hull-forms using advanced composites and corrosion resistant metals to enhance the capabilities of its vessels.

As a result of this concern, the Navy sponsored a study of stress relaxation in the hybrid composite-to-metal bolted connections that are used in US Navy vessels. The results of this study were reported in an article titled, “Influence of Stress Relaxation on Clamp-up Force in Hybrid Composite-to-Metal Bolted Joints,” by Vincent Caccese, Keith A Berube, Mauricio Fernandez, and Jean Paul Kabche of the University of Maine, and J Daniel Melo of Universidade Federal do Rio Grande do Norte, Brazil.

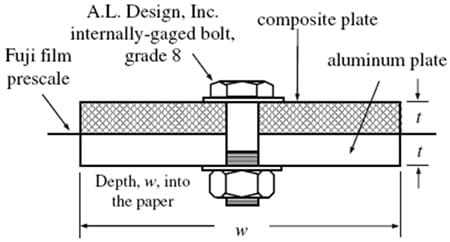

Tactile stress sensors were important tools that were utilized in this research. Figure 1 shows the Bolt Stress Relaxation Test Fixture. Fujifilm Prescale® film was placed between a composite plate and an aluminum plate, and the assembly was bolted together using a metal bolt. The Fujifilm Prescale® film is actually the tactile stress sensor that measured the pressure distribution between the composite and aluminum plates.

Fig 1: Bolt Stress Relaxation Test Fixture

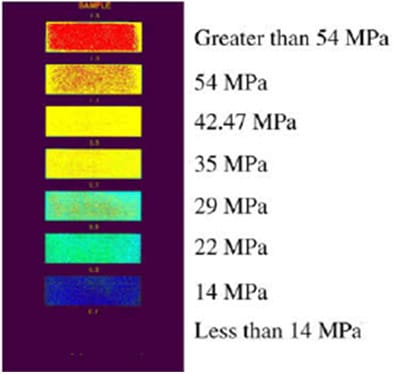

Fujifilm Prescale® film is an easy to use tool that reveals the distribution and magnitude of pressure between any two contacting, mating, or impacting surfaces. This pressure indicating sensor film is extremely thin (4 to 8 mils), and it is ideal for tight spaces not accessible to conventional electronic transducers. Like Litmus paper, the color intensity of the film (after being pressed) is directly related to the amount of pressure applied to it, the greater the pressure, the more intense the color. The film images can be scanned and converted via software to the color-calibrated images shown in Figure 2.

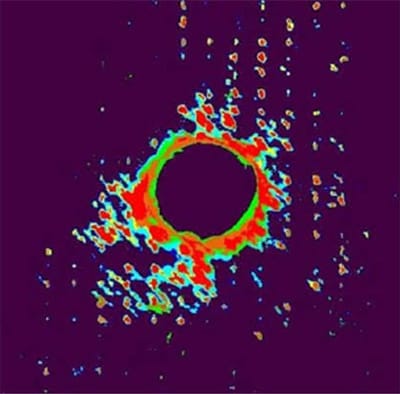

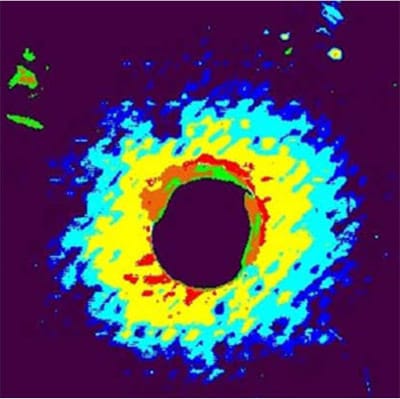

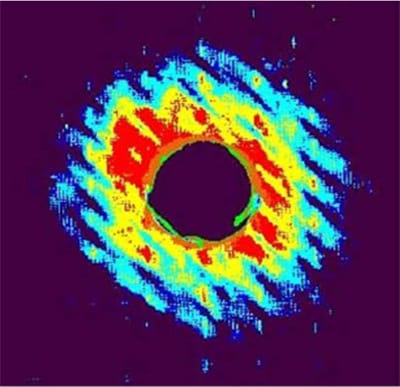

Figure 2 shows three pressure distribution contours for different test specimens and the pressure distribution color chart that was used to quantify the stress levels. The thickness of the specimens and their preload are (a) 25.4-mm thick with 66.72-kN preload, (b) 19.0-mm thick with 44.50-kN preload, and (c) 12.7-mm thick with 22.25-kN preload.

Fig 2a: 25.4-mm thick with 66.72-kN preload

Fig 2b: 19.0-mm thick with 44.50-kN preload

Fig 2c: 12.7-mm thick with 22.25-kN preload

Fig 2d: Pressure Distribution Color Chart

The Fujifilm Prescale® tactile stress sensor film indicated that the contact pressure was more evenly distributed for the thinner composite specimens, and the maximum stresses occurred at the edges of the bolt holes.