When two surfaces are pressed together, they frequently are not in perfect contact with one another. This can be a result of lack of parallelism, surface roughness, or surface rigidity. As a result, different degrees of pressure are exerted between the surfaces. The pattern of pressure magnitude is known as Surface Pressure Distribution.

Such surface pressure distribution is often problematic. For example, heat sinks are used to cool microprocessors in computers and electronic devices. Since conductive heat transfer is dependent upon contact area, uneven contact or pressure can result in inefficient heat transfer. Manufacturers need to measure the surface pressure distribution between mating parts during the design process to remedy potential problems. To accomplish this, they turn to Fujifilm Prescale®, Pressure Indicating Film, to quantify the surface pressure distribution.

Fujifilm Prescale® reveals the distribution and magnitude of pressure between any two contacting, mating, or impacting surfaces. Fujifilm Prescale® is a Mylar-based film that contains a layer of tiny microcapsules. The application of force upon the film causes the microcapsules to rupture, producing an instantaneous and permanent high resolution image of pressure variation across the contact area. The color intensity is proportional to the pressure. Figures 1–3 demonstrate the use of Fujifilm Prescale®.

| |

| Fig 1: Heat Sink | Fig 2: Fujifilm Prescale® between Heat Sink and Microprocessor |

| Fig 3: Fujifilm Prescale® Color Variations Show Surface Pressure Distribution | |

Figure 1 shows a typical heat sink (without its cooling fan). Figure 2 shows how Fujifilm Prescale® is inserted between the microprocessor and heat sink. Figure 3 shows the surface pressure distribution as indicated by the color change of the Fujifilm Prescale®.

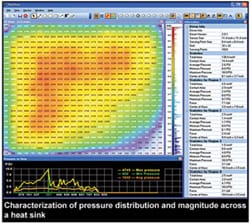

Fujifilm Prescale® shows the maximum pressure at any point between the surfaces. However, it is often desirable to know how pressure changes as a result of fastener torque during assembly operations. Tactilus® is a matrix-based sensor system that can provide time-dependent pressure information. Collected data are analyzed using Windows®-based proprietary software. Figure 4 shows a Tactilus 25 × 25 node sensor, and Figure 5 shows its data generated in Windows®.

|  |

| Fig 4: Tactilus® Sensor and Electronics | Fig 5: Tactilus Data Generated in Windows® |