In pulp and paper manufacturing and converting, the material being processed passes through contacting rollers. The nip is the point of contact of the two rollers. Capturing the nip pressure profile, by means of Fujifilm Prescale® film distributed by Sensor Products Inc., is important to help ensure roller uniformity and help prevent defects (Additional application glossary information can be found under the “Nip Impression Paper” topic.)

The Nip Pressure Profile has been discussed by Harry T. Loftin, Jr., a senior R&D engineer of Product Development at the Celanese® Acetate headquarters in Charlotte, North Carolina, in a paper titled, “Measuring Nip Roll Pressure: Tactile Measurement of Roll Pressures on Threaded-Roll Machines for Opening Cellulose Acetate Tow”. In this paper, Mr. Loftin states, “Setting optimum pressures on the pretension and threaded rolls of tow-opening machines is critical to the successful preparation of Celanese® Acetate tow for cigarette filter rod making. The band of acetate fibers (tow) must be processed to deregister, or open, the fiber crimp.” An incorrect Nip Pressure Profile can adversely affect the process and lead to defective filter rods. Figures 1 and 2 show Celanese® Acetate’s roll sets.

Fig 1: Pretension Roll Set |  Fig 2: Threaded Roll Set |

There are two types of pressure rolls on the tow opener. The pretension rolls, which prepare the tow for opening by the threaded rolls, consist of a smooth steel roll paired with a hard rubber roll (Figure 1). The threaded rolls may be either a single set of rolls or two sets of rolls in tandem, depending on the model of the equipment. A threaded-roll set consists of a steel roll with a threaded surface paired with a hard rubber roll (Figure 2).

The roll sets have gages for setting the pressure, but the gage reading can vary depending on the type of roll loading system employed. For example, the gages might display 1.5 bar when the actual pressure exerted on the rolls is only 0.75 bar. Furthermore, the gages cannot provide the actual Nip Pressure Profile, which is measured using Fujifilm Prescale® Pressure Indicating Sensor Film.

Fujifilm Prescale® works by virtue of microspheres that are coated onto the film substrate. These microspheres rupture at various predetermined stress levels. Upon the application of force, the film develops a permanent and irreversible color tone that identifies how much pressure to which the film has been exposed. The color intensity of the exposed film is directly related to the amount of pressure that has been applied to it, the greater the pressure, the more intense the color. By visually comparing the resultant film with a set of color standards, the operator can closely estimate the actual roll contact pressure.

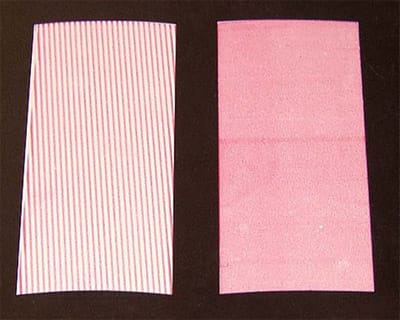

The film indicates both the magnitude and Nip Pressure Profile at the nip. This allows the operator to adjust the individual roll pressures to the required operating level. Figure 3 shows two examples of exposed Fujifilm Prescale® film.

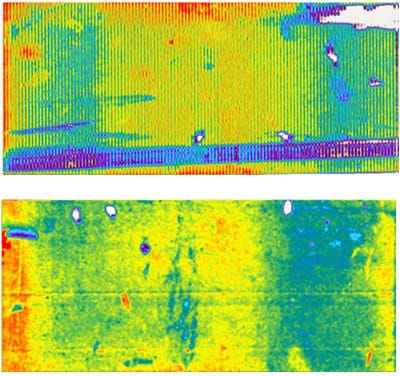

Fig 3: Exposed Film Strips from the Threaded Roll Set (left) and the Pretension Roll Set (right) |  Fig 4: Expanded Topaq® Nip Pressure Profiles from the Threaded Roll Set (top) and the Pretension Roll Set (bottom) |

The method as described above provides a quick, easy “litmus test” for approximating Nip Pressure Profile without additional equipment and with little downtime. Pressure readings are accurate within ±4%. For those users who require greater accuracy than can be obtained by a simple visual comparison, Topaq®, a sophisticated Windows®-based analysis system, may be used to read and evaluate the pressure film samples.

Topaq® provides a quick, yet thorough analysis of the pressure distribution and magnitude between any two surfaces that come into contact. This Windows®-based system renders high resolution, pseudo-color calibrated images that accurately reflect how force is dispersed. The system consists of a specially calibrated scanner and the Topaq® software.