Gasket contact refers to the tactile fit between a gasket and the mating surfaces being sealed by it. Ideally, intimate Gasket Contact must be maintained between the gasket and the flanges to assure that leakage does not occur. Such Gasket Contact is achieved when the gasket compresses to fill irregularities in the flanges and any gaps caused by flange distortion. (Additional application glossary information can be found under the “Gasket Interface” keyword in the Glossary.)

As a consequence of the Montreal Protocol on substances that deplete the ozone layer, CFC refrigerants are being phased out and alternate refrigerants are being introduced for refrigeration systems. As a result, new leak-proof compressor designs must be developed. Pressure indicating sensor film is a valuable tool for optimizing Gasket Contact and for validating Finite Element Analyses (FEA) of new designs.

A research paper that deals with this topic was written by Pavan P. Jorwekar, Yogesh V. Birari, and Mayur M. Nadgouda of Kirloskar Copeland Limited, Karad, Maharashtra, India. The title of this paper is, “Cylinder Head Gasket Contact Pressure Simulation for a Hermetic Compressor.” This paper elaborates the use of the FEA tool, ANSYS, to analyze the cylinder head and gasket content of a compressor. This analysis helped in finding the contact pressures across the gasket due to pre-torques applied through bolts. Design modifications were done for removing the low contact pressure zone areas on the gasket. The gasket contact pressure pattern obtained in ANSYS was validated using Fujifilm Prescale® film.

Fujifilm Prescale® is a unique, affordable, and easy to use tool that reveals the distribution and magnitude of pressure between any two contacting or mating surfaces. Figure 1 shows the four easy steps for using Fujifilm Prescale®.

Fig 1: Four Steps for Using Fujifilm Prescale® to Monitor Gasket Contact

Fujifilm Prescale® is a Mylar-based film that contains a layer of tiny microcapsules. The application of force upon the film causes the microcapsules to rupture, producing an instantaneous and permanent high resolution “topographical” image of pressure variation across the contact area.

Simply place Fujifilm Prescale® pressure indicating sensor film between any two surfaces that touch, mate, or impact. Apply pressure, remove it and immediately the film reveals the pressure distribution profile that occurred between the two surfaces. Conceptually similar to Litmus paper, the color intensity of Fujifilm Prescale® is directly related to the amount of pressure applied to it, the greater the pressure, the more intense the color.

Fujifilm Prescale® is extremely thin (4 to 8 mils) which enables it to conform to curved surfaces. It is ideal for invasive intolerant environments and tight spaces not accessible to conventional electronic transducers. It is perfect for analyzing Gasket Contact.

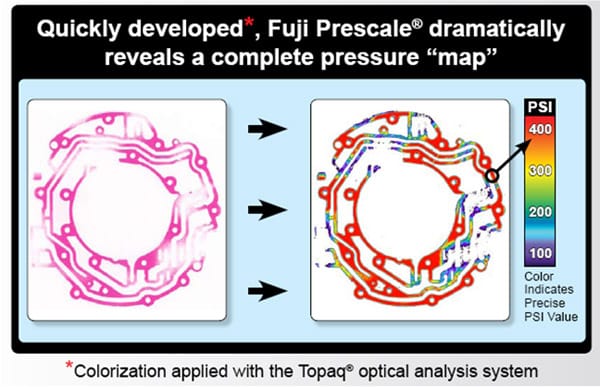

Used in conjunction with Fujifilm Prescale® pressure indicating films, Topaq® provides a quick, yet thorough analysis of the pressure distribution and magnitude between any two surfaces that come into contact. This Windows®-based system renders high resolution, color-calibrated images that accurately reflect how force is dispersed. The system consists of a specially calibrated scanner and the Topaq® software. Figure 2 illustrates how Topaq® analyses Gasket Contact.

Fig 2: Pseudo-color Pressure Distribution using the Topaq® Optical Analysis System to Analyze Gasket Contact

A simple pressure profile analysis can be performed in a matter of minutes using Topaq®. The system makes it extremely easy for an inexperienced user to extract and utilize important pressure imaging information. Simply scan in the exposed pressure indicating film, key in a few input variables, and Topaq® instantly generates full-color pressure maps and accompanying statistical data. Furthermore, Topaq® is accurate to within ± 2%, which is unprecedented in the field of tactile pressure measurement. Other features of Topaq® include 3D interpretation, image zooms, pressure line scans, and pressure distribution histograms.