A clamp is a device that secures objects to prevent their movement or separation by the application of inward force. Clamping Pressure can be defined as this force divided by the surface area being constrained by the clamp. Figures 1–3 show various types of clamps.

|  |  |

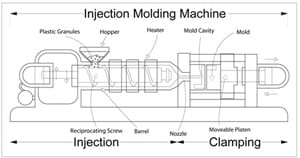

| Fig 1: Vertical Toggle Clamp | Fig 2: Collet | Fig 3: Horizontal Injection Molding Machine with Mold Clamping Section |

The vertical toggle clamp is used to hold down parts and assemblies. The black rubber pad exerts a compressive force on the parts being held down. The clamping pressure is equal to the compressive force divided by the contact area of the rubber pad.

The collet is a holding device used in lathes. It applies force against the circumference of cylindrical bars. The clamping pressure equals the clamping force divided by the surface area of the bar in contact with the collet.

The horizontal injection molding machine applies force to hold the mold closed. The plastic being injected into the mold exerts opposing pressure against the mold face. To assure that the mold does not open, the clamping pressure must exceed the injection pressure.

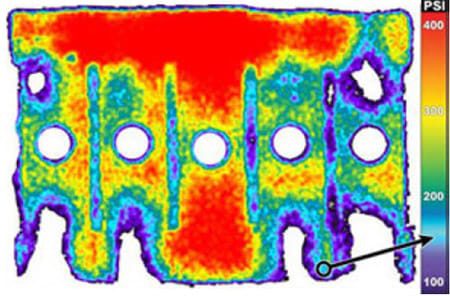

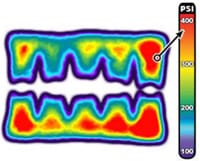

Futek, a US manufacturer of load cells and pressure sensors, experienced difficulty assembling some of its load cells to specifications. By performing several tests using Fujifilm Prescale®, pressure indicating film, the company found fluctuations in clamping pressure to be a significant factor. Fujifilm Prescale® showed inconsistencies in surface pressure between mating and contacting surfaces as shown in Figure 4. This discovery led Futek to redesign several of its clamps to incorporate silicone die springs to regulate the pressure more precisely.

Fig 4: Clamping Pressure Variations

Fujifilm Prescale® is a Mylar®-based film that contains a layer of tiny microcapsules. The application of force upon the film causes the microcapsules to rupture, producing an instantaneous and permanent high resolution “topographical” image of pressure variation across the contact area.

Simply place Fujifilm Prescale® pressure indicating film between any two surfaces that touch, mate, or impact. Apply pressure, remove it. Immediately, the film reveals the pressure distribution profile between the two surfaces. Conceptually similar to Litmus paper, the color intensity of Fujifilm Prescale® is directly related to the amount of pressure applied to it.

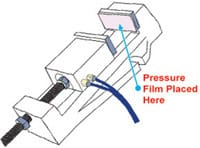

Fujifilm Prescale® is extremely thin (4 to 8 mils), which enables it to conform to curved surfaces. It is ideal for invasive intolerant environments and tight spaces not accessible to conventional electronic transducers. Figures 5–8 demonstrate the use of Fujifilm Prescale® and Topaq®.

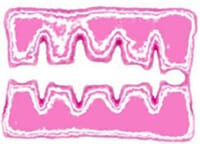

|  |

| Fig 5: Fujifilm Prescale® Film Placed Between a Clamping Interface | Fig 6: Fujifilm Prescale® film Before Topaq® Analysis |

|  |

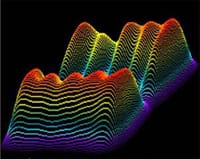

| Fig 7: Fujifilm Prescale® film After Topaq® Analysis | Fig 8: 3D Pressure Characterization of a Clamping Interface |

A Windows®-based system, Topaq® renders high-resolution, color-calibrated images that accurately reflect how force is dispersed. Topaq® can view, rotate and flip images in two or three dimensional space using four different color palettes. Images can be further enhanced by varying the number of colors displayed and applying a smoothing filter to display hidden detail.