Feel the Pressure

If you make products that touch the human body, you may need to characterize the contact pressure at the product’s interface.

The Tactilus® Human Body Interface sensor system dynamically maps surface contact pressure, using a sensor pad and software to produce a body map. The bedding industry consults with Sensor Products Inc. and uses Tactilus® Body Mapping in the design and sale of their mattresses.

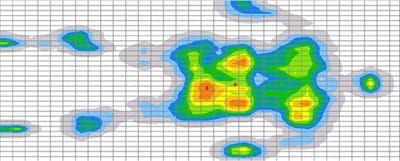

Imagine a mattress with a sensor pad laid on top. A person lies down on the sensor pad, applying pressure to it. The pad senses the pressure and sends the data to capture software where it is interpreted and displayed as a pressure map. Unlike conventional pressure sensors, such as a tire pressure gauge, Tactilus® actually provides dynamic tactile data interpretation of pressure as it changes and is distributed between two contacting surfaces.

In the mattress example, the compliant sensor pad conforms to the shape of the human body, dynamically reporting pressure. This technique allows mattress designers to tweak materials and support structures, in order to minimize body pressure points. Moreover, the sensor pad is re-usable, allowing multiple evaluations of any number of body types and proportions.

Designed to collect surface stress magnitude and distribution between two surfaces, the sensor pad conforms to curvaceous surfaces, lending its uses to a wide variety of applications such as evaluating the interface of a seat belt and occupant, creating uniform sofa cushion support, identifying finger pressure on a toothpaste tube, and collecting pressure on the body during impact crash testing.

The United States Air Force uses Tactilus® body-mapping technology to optimize component placement on the soldier carrier system, such as: armor, ammunition clips, radios, and batteries. Characterizing the surface pressure of the body armor on the soldier reduces neck and shoulder strain.

The tactile surface sensor pad is quite thin (0.7 mm (.0276 inch)) and is constructed of an array of sensor elements. Ranges can be measured between 0.1 PSI (0.007 Kg/cm²) to 100PSI (140.61kg/cm²). Tactilus® sensors are manufactured and calibrated to tight tolerances with accuracy of ± 10% and repeatability of ± 2%. The robust sensor design is electronically isolated with shielding that minimizes environmental electrical, temperature and humidity concerns. Meaning, the sensor system can be operated in a variety of conditions.

The sensor and data collection software is easy to use and understand. When pressure is applied to the sensor mat, the collection software reads and interprets the data. The software assimilates the data into a meaningful visual tool called a pressure map. Software directions are intuitive and compatible with Windows based operating systems. Because Tactilus® is lightweight, portable and wireless-ready, it has great utility in a wide variety of situations.

Testimony of the Tactilus® Body-Mapping Pressure System

“The Tactilus® pressure mapping system … shows us any pressure points that develop, not just when soldiers stand in place but also when they perform ballistic motions, such as jumping, running quickly, turning, crouching or crawling on their bellies,” said one of the project leaders, Dr. Evan Goldman, a professor of gross anatomy and physiology at Philadelphia University. “By viewing images and statistics from sensors located beneath their vests, we can see how these pressure points move with the body in real time as they perform their maneuvers.”