Article: Appliance Design

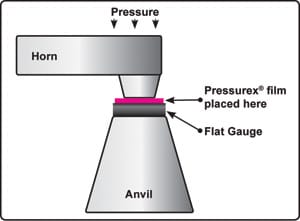

Routine use of Pressurex® during the set up of ultasonic welders provides an economical method to ensure proper contact pressure and alignment between the horn and the anvil. This results in welds of greater bond strength, lower rejected product, and lower base factory cost, according to the company. Pressurex® is a tool that reveals the distribution and magnitude of pressure between any two contacting surfaces. When placed between the horn and the anvil of the ultrasonic bonder, the film instantaniously and permanently changes color directly proportional to the actual pressure applied. The precise pressure magnitude (PSI or kg/cm²) is determined by comparing color variation results to a color correlation chat (conceptually similar to interpreting Litmus paper).The tool is thin (4-8 mils) and flexible, which enables it to conform to curved surfaces.