Solar cells (Photovoltaic Module Manufacturing)

Checking that press pressure of vacuum laminator is even

In the manufacture of solar cells, modules are formed by cementing the cells to the glass substrate with a vacuum laminator. If the press pressure is not even when this is done, defects will occur, such as damage to cells or wrinkles in the protective film. Although it has been possible to measure vacuum pressure, until now there has not been a way to directly measure the pressure actually applied to the cell.

Product used: Prescale (Extremely low pressure 4LW)

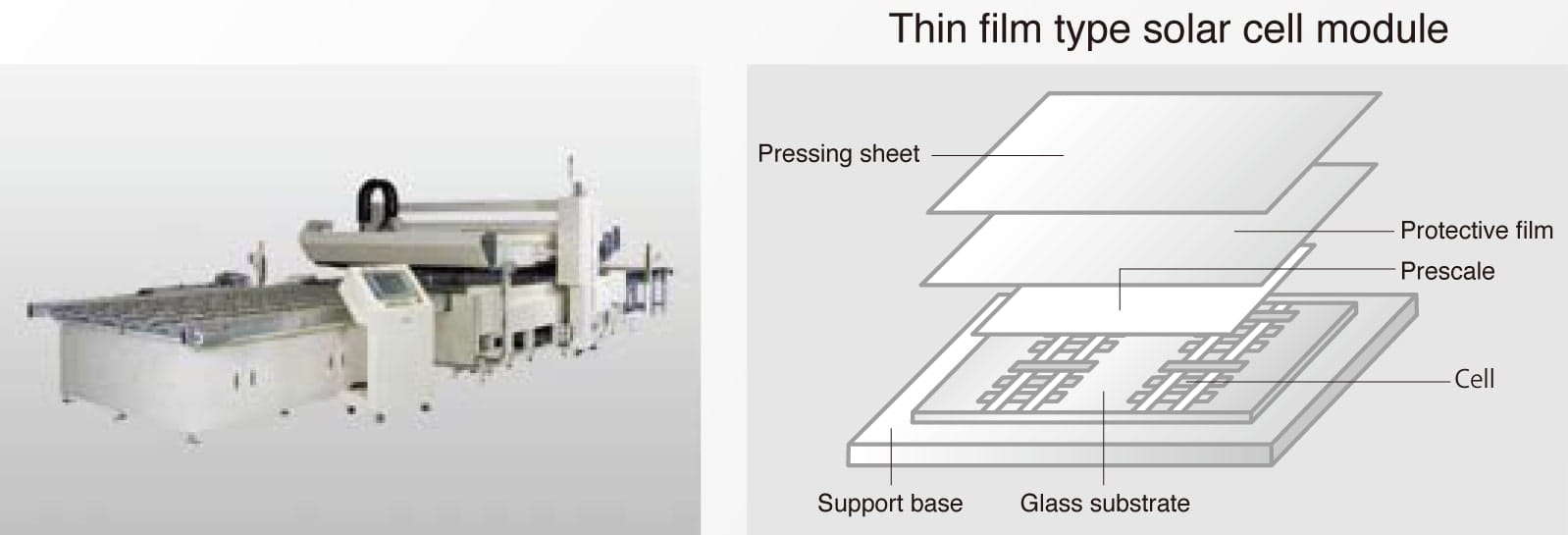

Place Prescale (4LW) over the glass substrate and apply pressure under normal conditions. Check whether the pressure was applied uniformly by examining the resulting color of the Prescale (in the case of the thin film type).

In addition, perform checks both with and without cells to assess the influence of cells on the pressure distribution.

In addition, perform checks both with and without cells to assess the influence of cells on the pressure distribution.

Formation of solar battery modules

[Thin film type] After cells are formed on the glass substrate, the module is formed by using a vacuum laminator to cement the protective film with a resin, such as EVA. [Crystal type] The module is formed by cementing together the completed cells and protective film by using a vacuum laminator to apply a resin, such as EVA.

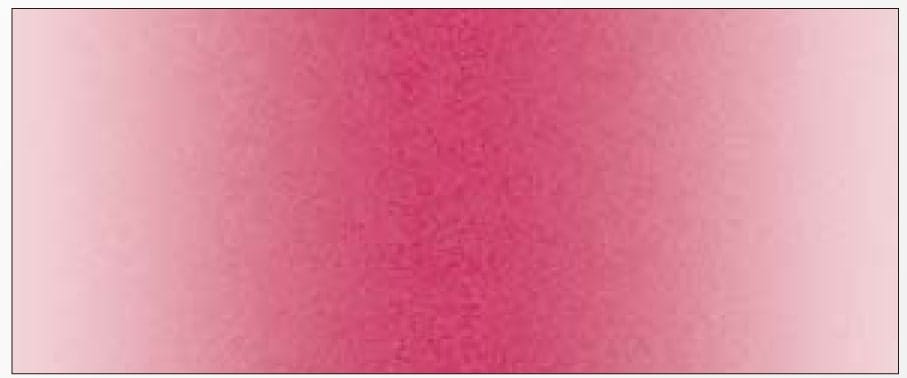

The images here show how pressure is actually applied to the cells and glass substrate. Process control is performed by comparing the wrinkles and cell damage with the color of the Prescale, and then fine-tuning the pressure accordingly, thereby preventing defective products.

[Good]

Pressure is applied evenly.

Previously, abnormalities could only be discovered at the stage of product inspection, after vacuum lamination.

Time savings

Without Prescale, much time is wasted in making adjustments when abnormalities occur.

Material savings

Without Prescale, large amounts of materials are wasted when abnormalities are found in the final inspections.

Without using Prescale

Defective products reduce yields only at the product inspection, so large amounts of materials are wasted.

Using Prescale

since abnormalities can be prevented by regular process inspections, productions runs under optimal conditions, due to suction-related transport thereby improving plant utilization