Manufacturing/maintenance services of office equipment

Maintaining high rendering quality by ensuring pressure uniformity during heat fixing

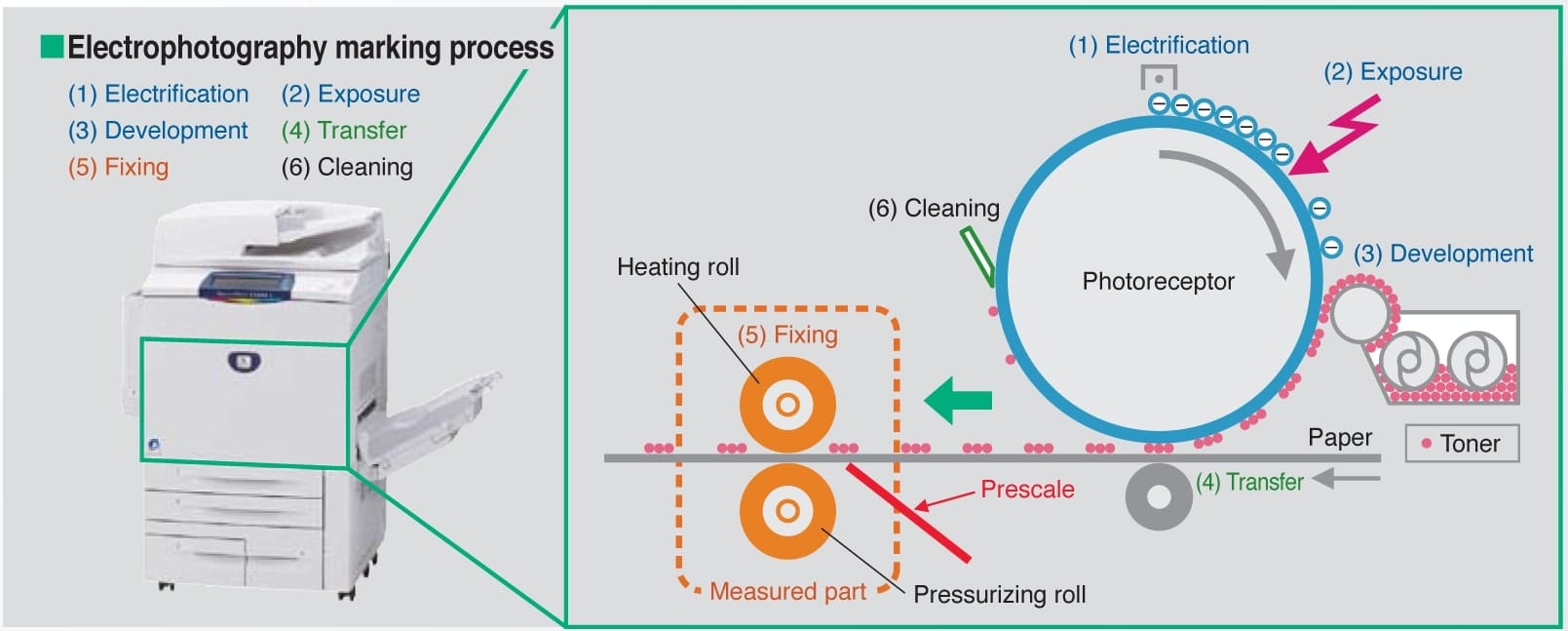

In electrophotography, a toner image (Figs. 1-3 below) is first formed on the photoreceptor and then transferred to paper (Fig. 4). Marketing is then completed using heat to fix the toner on t;he paper (Fig. 5). Heat fixing is typically applied by passing a piece of paper between a heating roll and a pressurizing roll, but if the pressure between the two rolls is not uniform, defective fixing or distortions in the papers may occur. In addition, the heating or pressurizing roll may become significantly worn after extensive use, thereby causing mechanical vibrations that alter the intial conditions of the device, resulting again in fixing defects or paper distortions.

Product used: Prescale (Extreme Low Pressure 4LW, Ultra Super Low Pressure LLLW)

Prescale is inserted between the heating and pressurizing roll

Application 1

Without rotating the rolls, the Prescale is nipped and pressure uniformity is checked according to the width of the colored lines.

Application 2

While rotating the rolls to pass the Prescale between the heating and pressurizing rolls, pressure distribution is checked for nip width and length.

Pressure distribution can also be checked while rotating the rolls at the actual temperature used for fixing.

Application 1

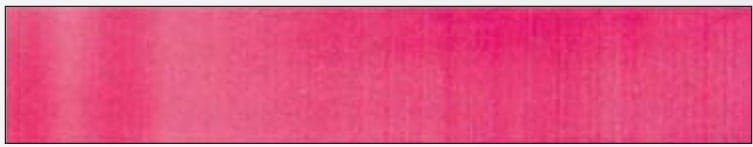

Judging roll pressure uniformity along paper width

[Uneven]

[Even]

Application 2

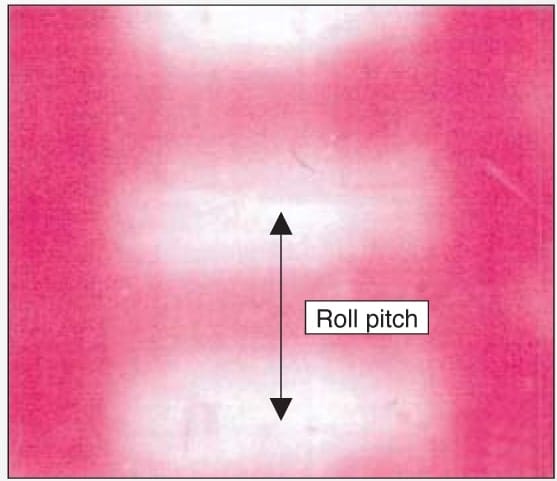

Judging pressure distribution along width and length

[Not good]

[Good]

Prescale enalbles fast, easy checking in actual heat-fixing conditions for a wide range of potential issues-uneven pressure distribution due to equipment conditions, irregularities in the shape of the heating or pressurizing roll, hardness irregularities, flaws, and uneven pressure distribution due to roll wear.

Higher efficiency in designing fixing units

Easier, more effective checking of heating roll, pressurizing roll, and other parts

Faster, easier analysis if defects occur

Without using Prescale

The only way to assess fixing performance is to conduct marking by actually passing paper through the device, resulting in loss of material and loss of time for adjustment.

Using Prescale

Checking can be done by simply nipping the roller or by checking the reaction in the heat-fixing process, thereby saving time and labor for defects analysis and adjustment.