What is Compression Force?

It is the application of power, pressure, or exertion against an object that causes it to become squeezed, squashed, or compacted. In the compression science definition, this type of force plays a crucial role in understanding how materials respond under pressure. Objects routinely subjected to compression forces include columns, gaskets, disc brakes, and components of fuel cells.

Since columns are used to support structures, they are always subjected to axial compression forces. By studying columns, one can get an understanding of the failures caused by compression forces. The effects of such forces depend upon the geometry of the column and the physical properties of the column material.

Under compression, short columns are dominated by their material strength limits.

Examples of Compression

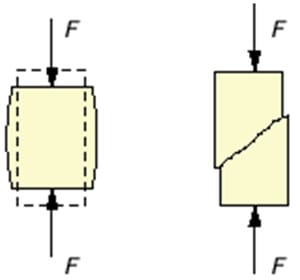

Figure 1 shows the failures that occur in ductile and brittle columns. However, as the length of the compression member increases, geometry and stiffness play important roles in the failure mechanisms.

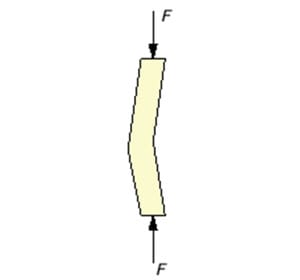

Figure 2 shows the failure of an intermediate column under compression due to kneeling. Kneeling occurs when the inelastic limit of the member is reached. For a long (slender) column (Figure 3), buckling occurs before the stress exceeds the strength of the column material. For example, pushing on the ends of a business card reproduces the buckling of a long column.

|  |  |

| Fig 1: Failures of Ductile (left) and Brittle (right), Short Compression Members | Fig 2: Failure of Intermediate Compression Member Showing Kneeling (Inelastic Buckling) | Fig 3: Buckling in a Long Compression Member |

As stated above, columns are not the only structures subjected to compression forces. Consider, for example, brake discs. They are designed to withstand the compressive forces of braking. However, interaction of the various brake components often causes brake squeal.

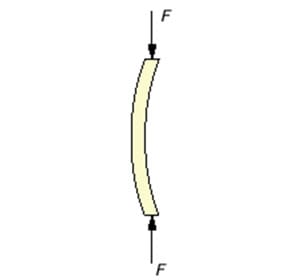

Bakar, Ouyang, and Titeica reported on, “Modeling and Simulation of Disc Brake Contact Analysis and Squeal” at the 2005 Malaysian seminar on Advances in Noise, Vibration and Comfort. In their research, they used Fujifilm Prescale®, pressure indicating film, to characterize the compression forces on brake discs (Figures 4 and 5).

| |

| Fig 4: Fujifilm Prescale® Film Placed on a Brake Pad | Fig 5: Fujifilm Prescale® Shows the Pressure Distribution Resulting from Compression Force on Brake Disc. |

Fujifilm Prescale® is a Mylar-based film that contains a layer of tiny microcapsules. The application of force upon the film causes the microcapsules to rupture, producing an instantaneous and permanent high resolution topographical image of pressure variation across the contact area. Simply place Fujifilm Prescale® film between any two surfaces that touch, mate, or impact. Apply pressure, remove it, and immediately the film reveals the pressure distribution profile that occurred between the two surfaces

The data obtained by using Fujifilm Prescale® helped Bakar, Ouyang, and Titeica conclude that a stiffer caliper and disc can eliminate unstable frequencies that caused brake squeal during the compression force of braking.

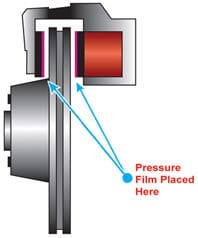

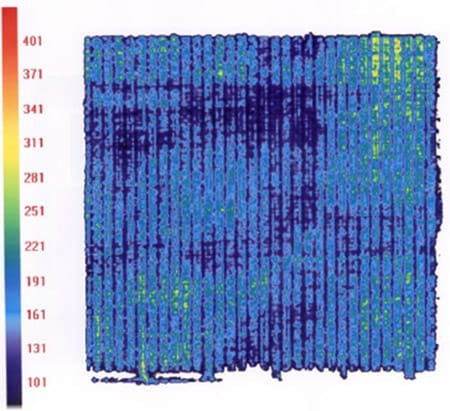

A second example of Fujifilm Prescale® being used for research into compression force was published by Mikko Mikkola (https://www.tkk.fi/Units/AES/studies/specials/mikkola1.pdf). This work was titled, “Modifications to a PEM Fuel Cell Stack.” It was used to measure contact pressures between the cathode flow field plate and the gas diffusion layer in a GlobeTech fuel cell.

The pressure distribution within the fuel cell is shown in Figure 6. The data show that pressure varied between 101 and 341 psi. These data helped Mikkola identify several flaws in the fuel cell design.

Fig 6: Pressure Distribution in GlobeTech Fuel Cell