Article: Paper Industry

Madison, NJ-based Sensor Products Inc. says that its new Sigma-Nip® is a technologically advanced electronic nip analysis system designed to measure roller profiles and diagnose roll alignment with unprecedented speed and cost-effectiveness.

The sensor system, which records nip width, renders obsolete time-consuming and inexact tools such as carbon paper and embossed foils. When Sigma-Nip® is used, loading problems, skewing and crown deficiencies are quickly exposed. It is more accurate, more durable and has a more powerful software user interface than any of its predecessors, says the company.

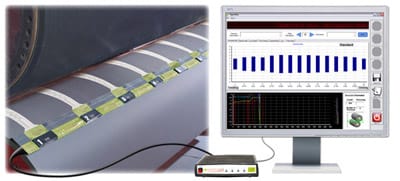

Sigma-Nip® consists of a chain of sensor elements and Windows-based software. The new sensors have been improved to withstand repeated high pressures and temperatures as well as routine exposure to grease and solvents. When placed between two ontacting rollers, the sensors capture data and ultimately record and assimilate nip width readings on a laptop while it is being viewed. Adjustments to rollers are made in real time while the sensors are in the closed (non-rotating) nip. Easy-to-interpret statistical data and graphical displays, which are transmitted via wireless or through a USB port, update continuously as technicians perform tests and adjustments.

Taking only minutes to deploy across the roller face by just one person, Sigma-Nip is useful for both ongoing maintenance and during equipment setups and shut-downs. As a quality con¬trol tool, Sigma-Nip facilitates evenly loaded roller sets that are much less likely to cause web breaks and down time. It improves web control and print quality by reducing uneven paper pulling, which can lead to sheet walking, wrinkles, jams and mis-registration. By virtue of routine tests, Sigma-Nip® allows the user to greatly extend blanket life.

"Sigma-Nip® has come a long way from concept to being a reliable, easy-to-use nip profile measuring tool," according to Mike Stoltz of Metso Paper. "Being able to save and review the entire real-time data from nip closing to nip opening is extremely useful, however, the ability to correlate accurate nip width data to roll deflection is an exceptional benefit." The portable Sigma-Nip system has its own carrying case. The same sensor chain can be used to measure different-sized rolls. Nip widths from 0.05 in. (0.13 mm) to 9 in. (22.9 cm) can be measured, and pressures from 40 psi (2.8 kg/cm²) to 3,000 psi (211 kg/cm²) can be withstood, making Sigma-Nip® potentially usable throughout the machine with small converting rolls as well as calender stacks.

Minimal computer knowledge or training is needed since the system prompts users through the few steps needed for installation and set up. Software enhancements include a Comparison Mode, where up to three nip-width readings can be viewed simultaneously. An Alignment Tool instantly draws a line to indicate nip width variations.

Sigma-Nip® has been tested and installed in web-based environments around the world. Demonstrations can be arranged.