Article: Woodworking International

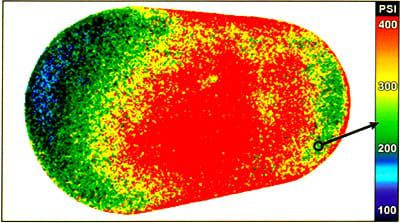

Pressurex® film used in a lamination press test

Sensor Products Inc. introduces Pressurex®, a contact surface pressure indicating sensor film. The film is used in assessing pressure magnitude and distribution between any two contacting or mating surfaces. In wood production processes, Pressurex® is used to measure pressure distribution of lamination presses as well at the nip of roller coating machines. Improper calibration of nip rollers and lamination presses can result in defective products. Pressurex® aids in calibrating nip width contact, and help to ensure proper alignment of heat seal machinery. The film is so sensitive that it will reveal voids, pits, microcracks, warping and surface aberrations. Pressurex® film indicates pressure from 2 – 43,000 PSI (0.14 – 3,000 kg/cm² ) and is available in seven different pressure ranges. It comes in the form of a thin Mylar roll or sheet that can be cut and is physically similar in thickness to paper. The sensor film changes color permanently and instantly when placed between contacting or mating surfaces. The intensity of the color change is proportional to the amount of pressure applied, allowing the user to quantify the stress characteristics across the surface. Precise pressure magnitude can be determined by comparison of the sensor film to a color calibration chart (conceptually similar to interpreting Litmus paper). No additional training or instrumentation is required.

Pressurex® is a valuable aid for any wood processing situation where materials or solid surfaces come in contact with each other and the distribution and/or magnitude of contact pressure needs to be determined. It is also an inexpensive method to determine whether accurate and consistent pressure is being applied in accompanying clamping operations, as well as bolted joints, gaskets, heat seal elements and many other industrial operations.