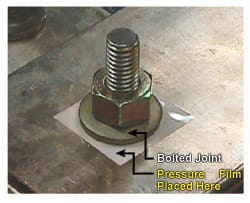

The bolts, in a bolted joint, exert force upon the parts being clamped together. This results in pressure at the interface of the joint. This pressure is called Bolted Joint Pressure. In published literature, much of the work assumes that the contact pressure is uniform at the interface. Unfortunately, interface pressure distribution is highly non-uniform due to dimensional irregularities, surface roughness, uneven bolt torque, and internal and external forces.

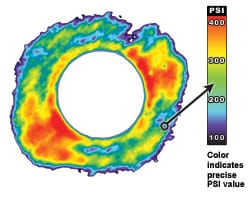

Since the average contact pressure is a linear function of bolt torque, it can be used for establishing bolt torque values. However, research studies on bolted joint pressure usually rely on finite-element analysis in order to study interface pressure in more detail. The results of such an analysis on a brake disk and wheel carrier were presented by Tirovic and Voller and are shown in Figures 1 and 2.

|

|

| Fig 1: Fujifilm Prescale® Film Places Between a Bolted Joint | Fig 2: Fujifilm Prescale® film AFTER Topaq® Analysis |

To verify the FE analyses and further investigate pressure distribution at the brake disc/wheel carrier interface, measurements of the contact pressure were conducted by using Fujifilm Prescale® pressure indicating film. The film changes from white to shades of red with the color intensity directly proportional to the applied pressure. Fujifilm Prescale® was placed between the clamping faces and the components bolted together. The bolts were tightened to their nominal torque.

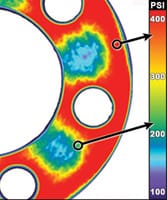

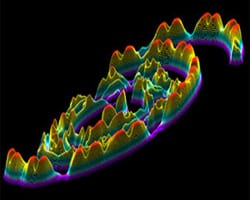

After 10 seconds, the bolts were removed and Fujifilm Prescale® was sent to Sensor Products for analysis. The results obtained from the analysis include two-dimensional and three-dimensional pressure images, as shown in Figures 3 and 4.

|

|

| Fig 3: Two Dimensional Contour Plot | Fig 4: Three Dimensional Contour Plot |

High pressure occurs around the bolt holes, and low pressure is found between the bolts. High pressure is also seen close to the internal diameter concentrating at the regions close to the bolt holes. The pressure reduces from the internal diameter towards the outside diameter of the contact area. The bolt holes continue to influence the pressure distribution close to the outside diameter.

Fujifilm Prescale® results are very close to the predictions from the finite element analysis, confirming that FE modeling can reliably predict pressure distribution in bolted brake component interfaces.